Product Search...

If you know the product or keyword you require enter it below:

Latest News

Resources

About Us

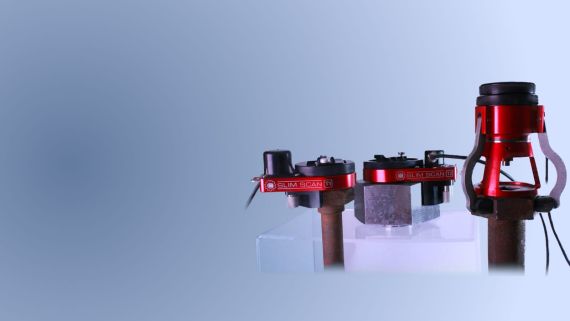

Pioneering Ultrasonics in NDT Industry.

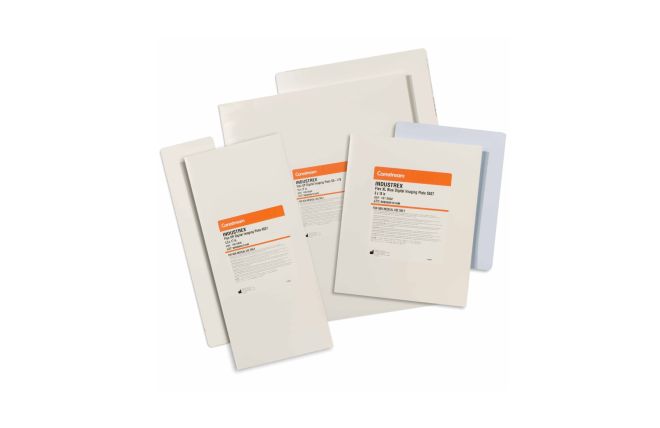

Whether it is conventional, phased array or FMC-TFM ultrasonic technology, Sonatest is a significant partner in providing Non-Destructive Testing solutions to many industries, including transportation, aerospace, power generation, manufacturing, NDT service and oil and gas to name but a few.

Our products are used by the world's leading companies such as Boeing, Airbus, Shell, Eon, Network Rail and are designed to give the user a powerful tool that is easy to use and will withstand the harsh environments in which NDT is carried out.