Phased Array Inspections

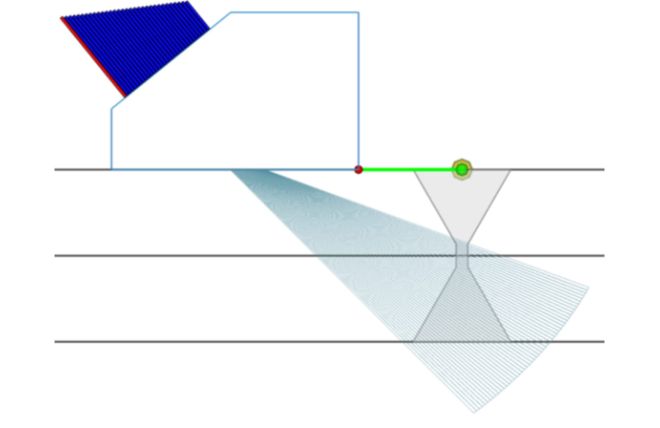

A Phased Array (PA) inspection is an advanced ultrasonic technique that uses transducers with multiple elements to create sound waves in a material. By ‘firing’ elements in a calculated sequence, beams can be created at a chosen angle and focal distance.

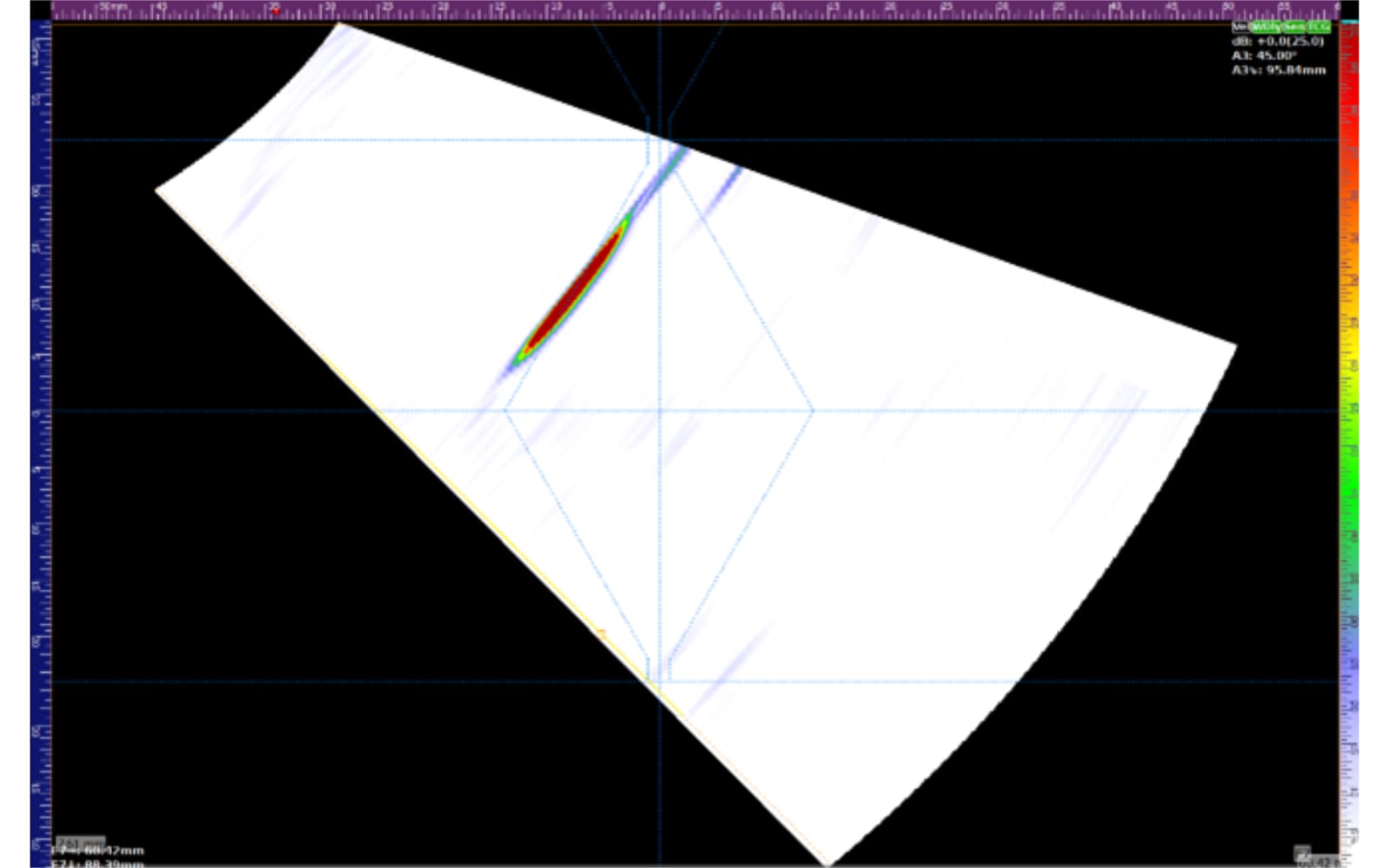

Creating multiple angles in the same scan, e.g. 45° to 70°, will create a ‘sectorial scan’, allowing the user to inspect entire welds from a single position.

Basic Principals

A Phased Array inspection involves firing individual elements at calculated intervals to create a wave that propagates in the material at a chosen angle and focal point. This relies on the principles of wave interference, both constructive and destructive interference.

The system calculates the timing delays to fire each element to create a wavefront using constructive interference, using different timings, the system can produce waves for a range of angles and focal points. This calculation is called a Delay Law, and when combined with other delay laws, e.g. 45° to 70° this is called a Focal Law.

Method Advantages

The Phased Array inspection has distinct advantages for users over conventional UT inspection. As a single focal law can cover a full weld from one position, the inspector can collect data for a full weld length in a single scan, saving time.

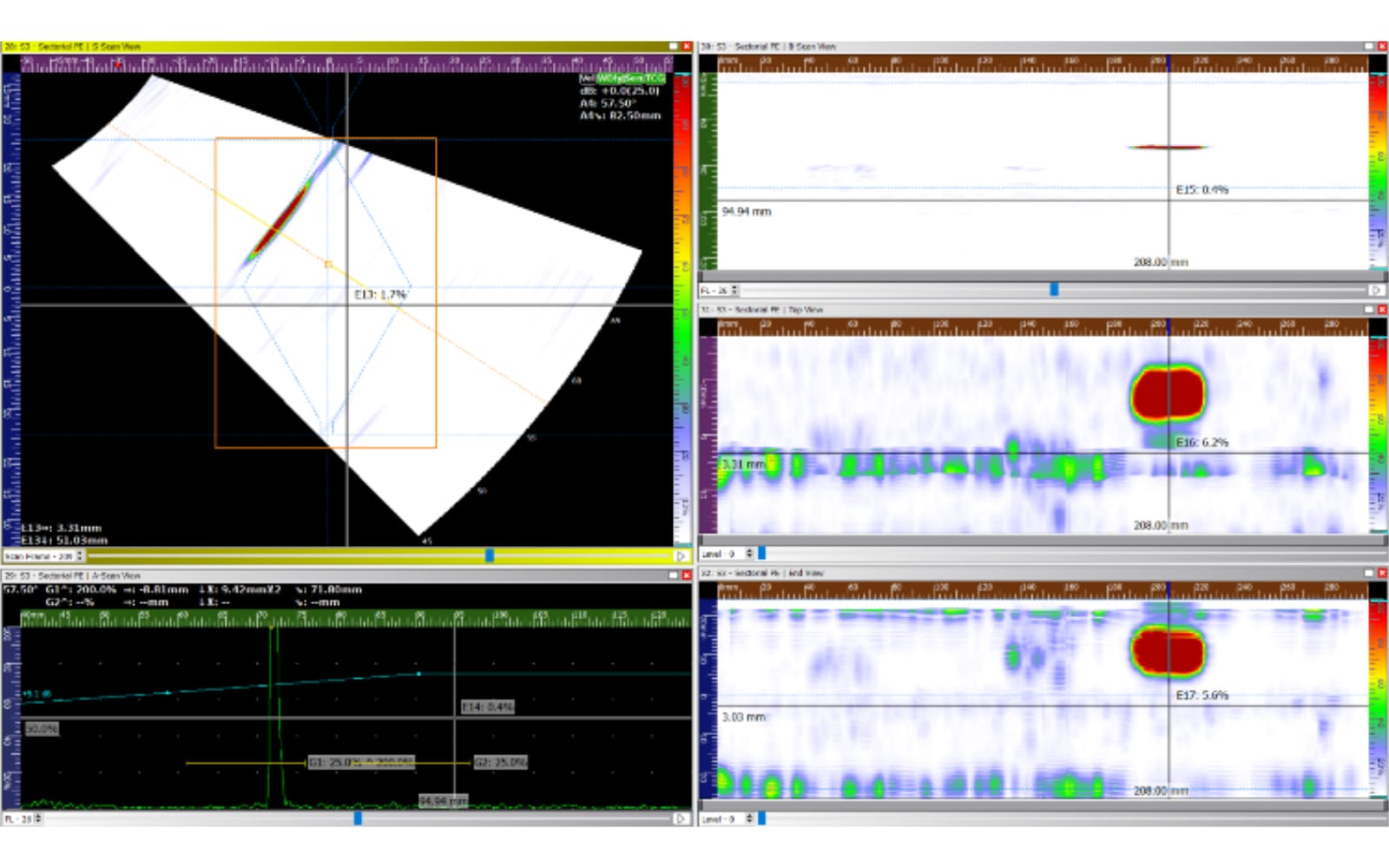

Secondly, inspection data can be displayed in multiple ways that help the inspector identify defects quickly. Top-down views, side views, weld profile views, and 3D views all help interpret results.

Equipment

At Sonatest, we manufacture, design and supply all the equipment needed to carry out PA inspections for any application. Follow these links to see our Phased Array Equipment, Phased Array Transducer and Wedges, Scanners, and our library of application notes, solution notes and educational material.

Applications

Ultrasonic phased array inspection covers a wide scope of applications, and new uses are being developed constantly. A few examples are given below.

Weld inspections – Phased Array inspections are a widely accepted technique for metallic and plastic weldments, including austenitic stainless-steel weldments.

Corrosion Mapping – Automated and manual PA scanning techniques provide a full high-resolution picture of corrosion in materials such as pipelines or storage vessel shells.

Composite structure assessments – PA can provide details on composite panel defects such as laminations, porosity, and ply drops. Honeycomb bonding checks can also be carried out easily.

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.