Scanners

Ultrasonic testing is a practical and versatile diagnostic method which allows for non-destructive examination of your components. Sonatest are a leading supplier of ultrasonic scanners and testing equipment, offering portable, advanced solutions to support diverse inspection requirements.

Non-Destructive Ultrasonic Scanning

Ultrasonic scanners use high frequency sound waves to detect flaws and anomalies in the material of your component. Where anomalies are found, the sound waves create an echo which is evaluated by specialised testing instruments.

Ultrasonic inspection can be manually performed, or fully integrated solutions can be created and configured to your requirements. Ultrasonic scanners provide accurate and efficient scanning. Our ultrasonic scanners work with specialised software to control the scan and acquire the scan data. From corrosion mapping to weld inspections, our range of scanners could be the solution you are looking for. These systems are based on years of industry experience and are supported by dedicated tools and technical support to ensure reliable results.

Scanners Frequently Asked Questions

Ultrasonic scanners are devices that utilise encdoded wheels or clamps to control a full probe motion. Some scanners are built for multi- single probe, probe setups or both. Scanners can be used for maintaining specific patterns like lines, rotation, or raster scans for instance. The AXYS is a single wheel scan to track the main line axis. The CREO models focus on rotation and bolt clamping scanning, which are crucial for a constant offset at providing good imaging results. These scanning systems often include smart features that enhance data acquisition and operator workflow.

There are specific scanner models that excel at pipeline scanning while bolt require a unique design. Products like the STIX Upgradeable or STIX Long Seam are used to inspect welding quality on pipes to guarantee perfect positioning. They also work on flat surfaces. The Bracelet is made for small diameter pipes (1.54 cm/0.5 inch to 30cm/12 inches). The WheelProbe is not a scanner, but its wheel tracks the linear move, so it makes a great mapping tool for flat or circumferential scan. These scanning systems often include smart features that enhance data acquisition and operator workflow.

Scanners used for NDT can be split into two versions: Manual and Semi-Automated scanners.

Manual scanners are handheld, and the position and movement are controlled wholly by the technician, this can include the use of an encoder.

Semi-automated scanners use fixed track or magnetic wheels to locate the scanner; the movement of the scanner in a particular axis can be manually driven or controlled automatically using motors. These models are ideal for teams conducting a detailed search for flaws in industrial settings.

Sonatest offers a variety of ultrasonic scanning products, such as:

- AXYS: A universal encoding clamp designed for single-axis inspections.

- CREO: Bolt scanners capable of handling encoded scanning of stud diameters ranging from 1” to 3”.

- Odi and Odi II: Single axis scanner; Compact encoders suitable for placements in tight spaces or for manual TOFD scanning (ODI II).

- Bracelet: Tailored for phased array inspection of circumferential welds in small bore pipework, particularly where access is limited.

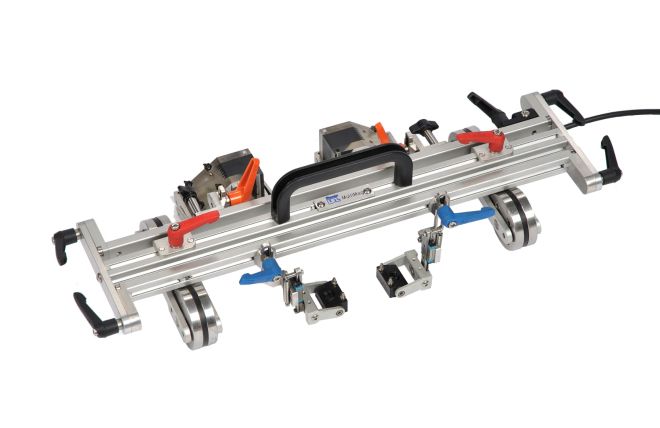

- STIX, MultiMag & Magman: Flat or Circumferential welds. It can drive 4 to 12 probes at the same time.

- STIX Long Seam: Two-probe magnetic scanner that provides an innovative solution for longitudinal weld inspection.

These specialised tools cater to different inspection needs across various applications, delivering efficient, portable, and advanced solutions supported by robust systems and expert technical support.