FMC and TFM

Ultrasonic Full Matrix Capture (FMC) is an advanced data acquisition technique used in Non-destructive Testing (NDT). The Total Focusing Method (TFM) is an advanced imaging technique that uses ultrasonic data to produce a high-resolution image that is focused at every pixel in the image.

Overview

FMC and live TFM are relatively new methods for portable NDT applications. In this short time, TFM has revolutionised defect detection, characterisation, and imaging.

Compared to phased array focal laws, it is simple to set up. All you require is a Region of Interest (ROI) and a good knowledge of ultrasonic principles to set the correct propagation modes for the expected defects.

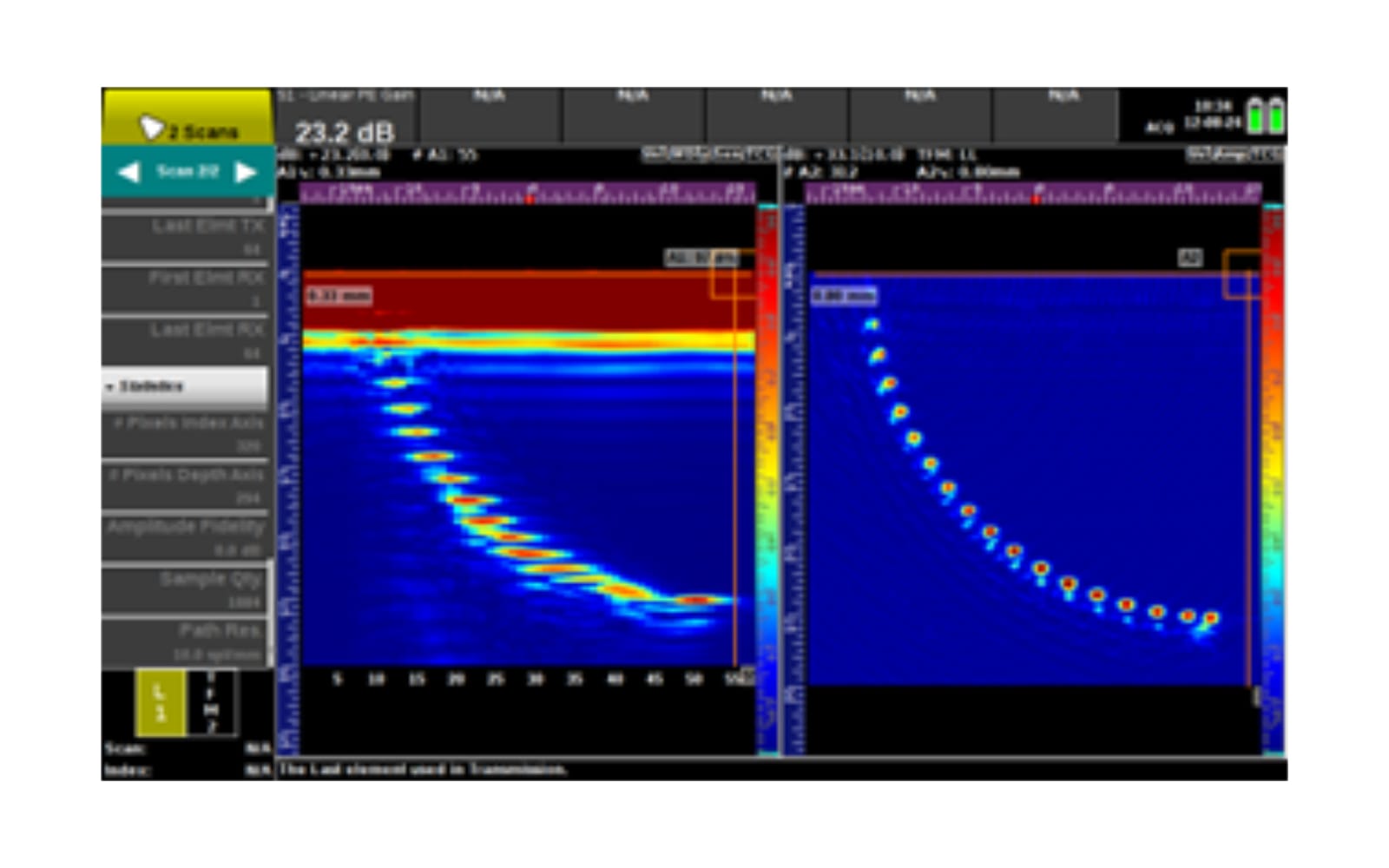

The VEO3 and UTStudio+ provide unmatched control over FMC / TFM settings, enabling the user to get the best scan results.

What is FMC

FMC is an advanced method of data collection using phased array (PA) transducers. Firing single elements at a time and recording every possible transmit-receive path for each element in the array, FMC gathers 100s -1000s of A-Scans for the inspection area.

This large data set contains an incredible amount of information on the inspection target. The data is then used in post-analysis through imaging processes such as TFM to view the inspection area in multiple ways, bringing to light defect indications and features within the target.

What is TFM?

What is TFM?

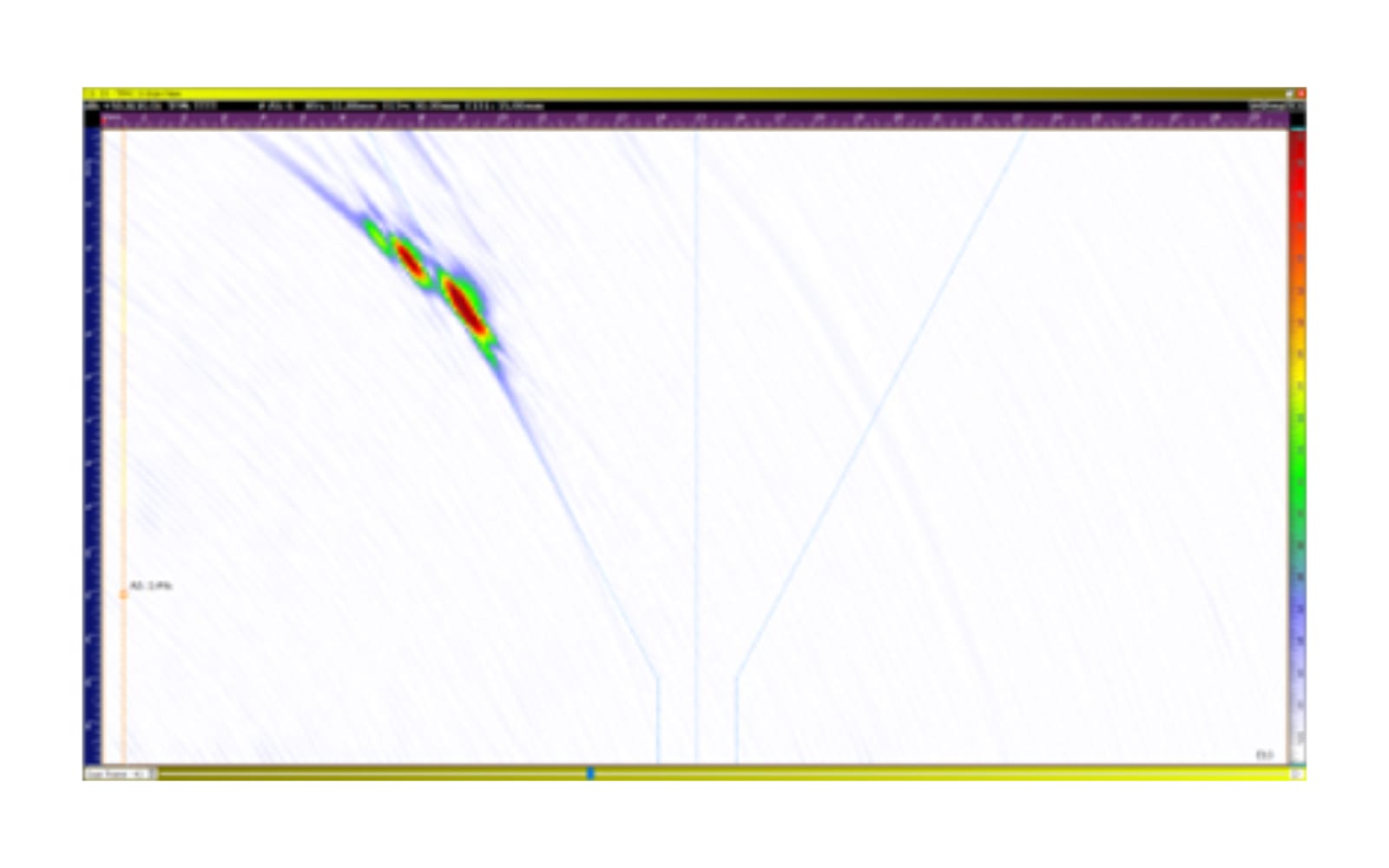

TFM is an advanced post-processing technique that uses FMC data to create high-resolution images of an ROI. The user defines an area within the inspected part (ROI) and defines a resolution for the area. TFM then uses the thousands of A-Scans collected by FMC and combines them all for each pixel in the window. This creates an image that is synthetically focused in every pixel and has an excellent signal-to-noise ratio.

In ‘live TFM’ this is carried out in real time one the screen for immediate results.

Advantages of FMC/TFM

FMC/TFM inspection provides a high-resolution, detailed view of a whole inspection area that is optimally focused at every point in the ROI, enhancing image resolution and defect detection.

The recorded FMC strategy is a powerful data structure that allows many imaging algorithms, such as standard delay and sum, delay multiply and sum, intermodal imaging, and many more.

TFM can be used in the same scan as phased array and TOFD, providing supporting information for the general inspections already being carried out.

Equipment

At Sonatest, we manufacture, design, and supply all the equipment needed to carry out FMC / TFM inspections for any application. Follow these links to see our Phased Array Equipment, Phased Array Transducers and Wedges, Scanners, and a library of application notes, solution notes, and educational material.

Applications

FMC/TFM inspections can be carried out on a wide range of materials and applications, a few examples are given below.

Weld inspections - Weld inspections and TFM inspections of welds provide high fidelity images of cracking defects and help in the detection of rounded indications such as porosity and slag.

High Temperature Hydrogen Attack - TFM is ideal for detecting the initial stages of HTHA (High Temperature Hydrogen Attack). Its capability to show small defects is widely used in materials where HTHA is a failure mechanism.

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.