Time of Flight Diffraction

Time of Flight Diffraction (TOFD) is an advanced ultrasonic Non-destructive Testing (NDT) inspection technique. Developed for the nuclear industry to improve defect sizing accuracy.

TOFD has been in the field since the 1970s and is the chosen method for many applications, including weld inspection, weld root erosion inspection, High Temperature Hydrogen Attack (HTHA) and many more.

Basic Principles

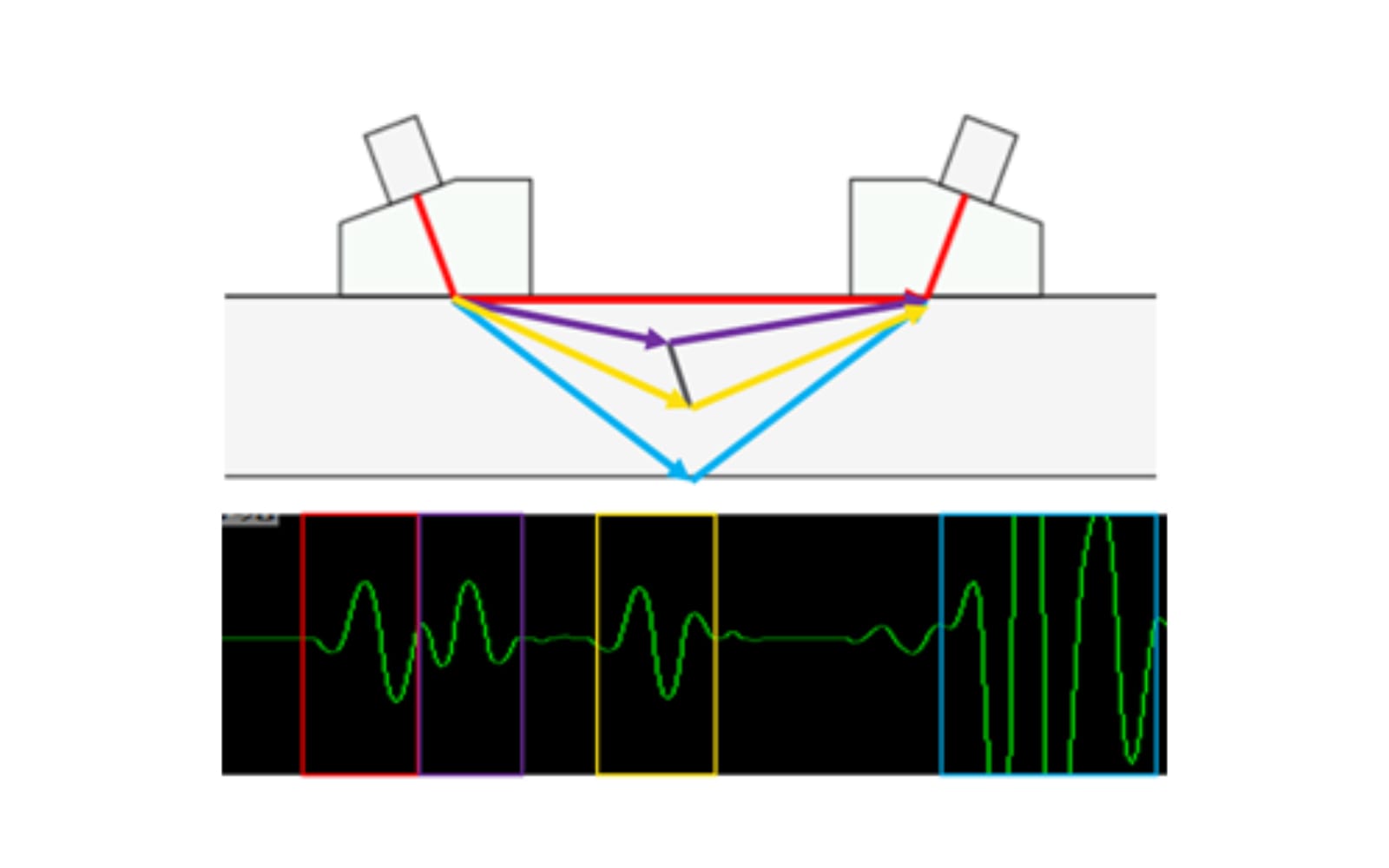

In ultrasonic inspections, most methods use ‘reflected’ signals to locate defects. In these methods, a pulse is transmitted into the material; if this signal hits a defect, some sound is reflected to the probe and detected. In addition, to the reflected signal, diffracted signals are produced at the tips of the defect: these signals that TOFD aims to detect.

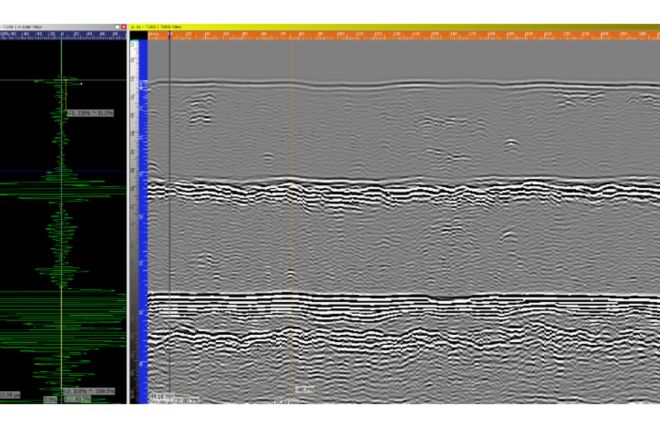

TOFD uses two transducers in a pitch-catch format on either side of the target area. The transmitter emits the ultrasonic pulse, flooding the area with sound, the receiver detects the signals as they come to the transducer.

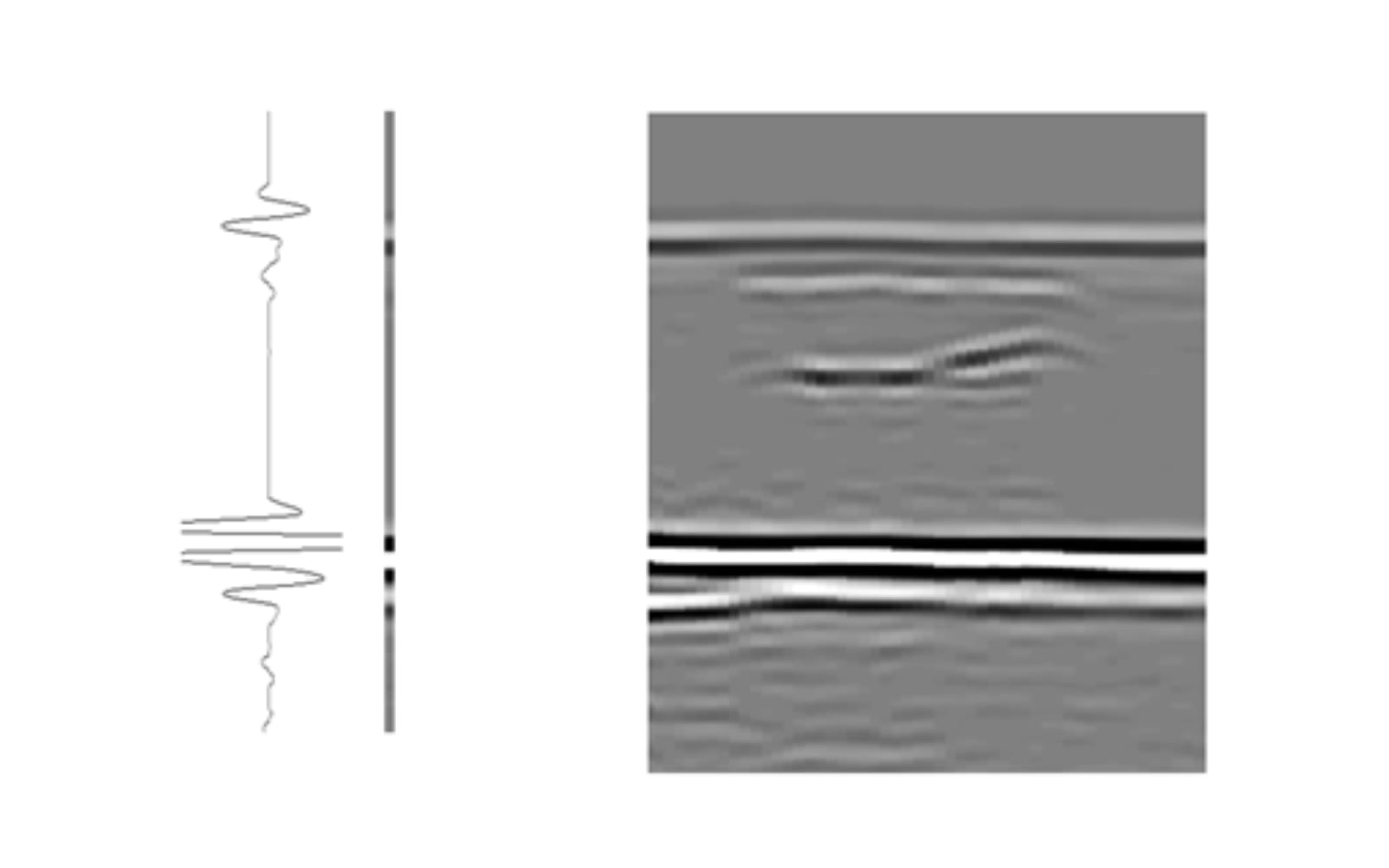

The system displays the return signals in order of the time they are received. In a plate with no defects, this is the ‘lateral wave’ first (surface signal), ‘Compression wave back wall’ and then the ‘Shear wave back wall,’ if defects are present, the top and bottom tip diffractions will appear in between these signals.

Method Advantages

TOFD is a remarkably simple technique to setup and gather data, and due to the small data size, large areas can be scanned quickly in a single pass.

TOFD is often used as an accompanying technique to PA (Phased Array) and is easy to add into a multi-scan setup for a wider set of data for your inspection.

TOFD generates a precise A-scan phase signal that is useful for height measurements. When the conditions are ideal, the positive or negative wave position provides an insightful analysis.

Equipment

At Sonatest, we manufacture, design, and supply all the equipment needed to carry out TOFD inspections for any application. Follow these links to see our Time of Flight Diffraction Equipment, TOFD transducers and wedges, Scanners, and our library of application notes, solution notes and educational material.

Applications

TOFD inspection is used for a wide range of applications. A few examples are given below.

Weld inspections – TOFD inspections are widely used on metallic and plastic weldments because it uses compression waves. It has a particular strength in austenitic materials either as a supporting technique for a phased array or as the sole method.

Weld root erosion – Weld root erosion or preferential attack is the loss of material from the heat-affected zone of a weld. This presents itself as loss along the fusion faces of the weld starting at the root; TOFD is an ideal method for detecting and providing an accurate reading on the remaining wall thickness where other methods can struggle.

High-Temperature Hydrogen Attack (HTHA) - TOFD can be sensitive to inter-granular cracking and is a great method for detecting early-to late-stage HTHA. When monitored over multiple inspections, cracking

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.