NDT Service Providers

NDT service providers are at the frontline of inspection, providing the skills, experience and expertise required by this industry.

- They are looking for value (Veo3 and Wave on the edge features)

- Rugged for all kinds of environments

- Devices and techniques people are already trained on

- Fast learning curve supported by simple interfaces

- Support/upgrade/documentation speed so you never deal with long downtimes

Sonatest boasts a rich history of manufacturing world-leading ultrasonic equipment. Our products are equipped with unique tools and features that not only enable technicians to conduct inspections to the highest standards but also ensure a seamless user experience, thereby enhancing your business's service quality. For more details, our UT systems can be explored through the links provided below.

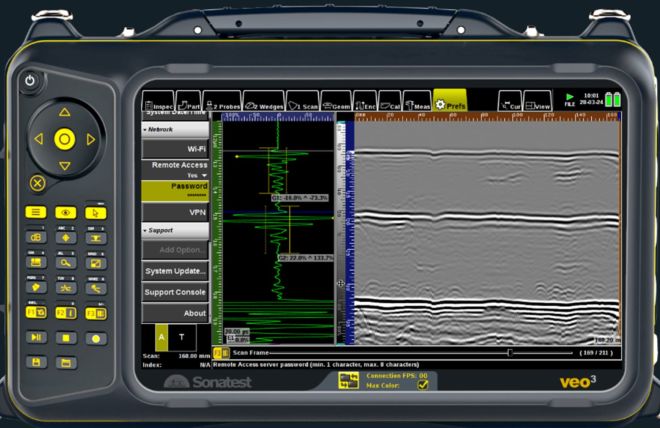

- VEO3

- Phased Array S-Scan and L-Scan

- Time of Flight Diffraction

- Live TFM

- TFMi

- WAVE

- Ultrasonic inspection

- Interactive scan plan

- CAD download scan plan

- Wi-Fi connectivity

- Digital Flaw detectors

- Proven conventional UT systems

- Thickness gauges

- UT Transducers

- Phased array transducers and wedges

- TOFD Transducers and wedges

Frequently Asked Questions

Ultrasonic testing (UT) plays a crucial role in maintaining the safety and reliability of assets. NDT Inspections should be impartial; This is why many companies use service providers to carry out their inspection programs on their behalf. Sometimes, increased NDT demands occur at specific times such as outages / shutdowns, service providers can provide additional personnel to increase the NDT resource for the specific project.

Ultrasonic testing is a non-destructive technique that identifies subsurface defects, thickness reductions, or weld inconsistencies in critical components. By detecting issues early, it helps minimise downtime, extend asset lifespans, and optimise maintenance schedules.

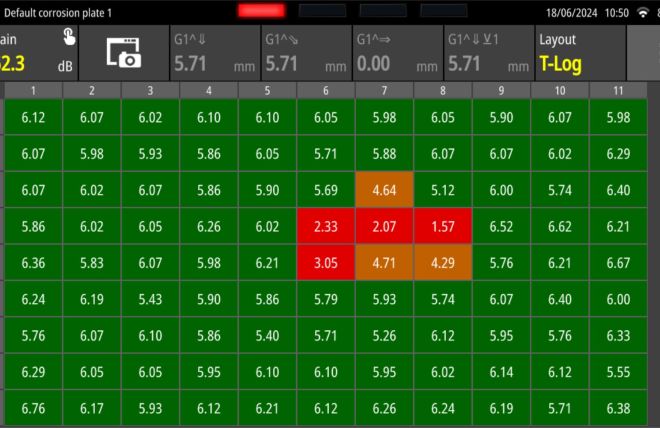

Service providers are a key player at gathering quality data over asset. They pick the best technique, so the mapping result is exactly as wished by the asset owner. This way, the data can be input in their risk-based inspection (RBI) software.

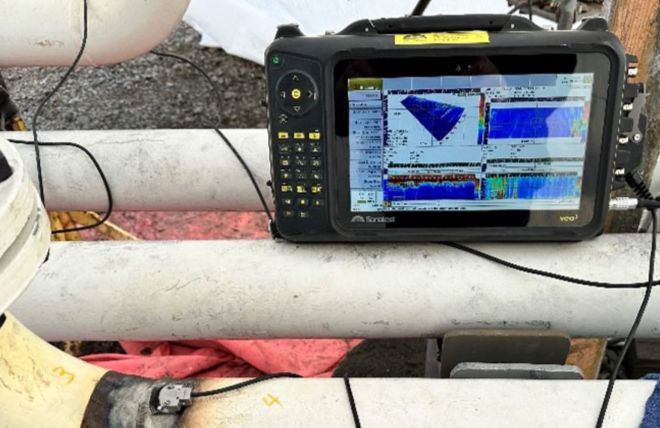

Pipelines and pressure vessels are subject to high stress and potential corrosion. Ultrasonic testing allows for accurate assessment of wall thickness, detection of cracks, and identification of internal defects without dismantling or halting operations, ensuring both safety and cost-efficiency.

UT survey provides valuable inner mapping data but together with laser data, the OD and ID data can be processed by a finite element analysis software. Accurate simulations can then predict maximum pressure levels, and the asset owner can decide to simply reduce the pressure level or avoid an unnecessary repair.

Service companies want an instrument with a high technology value to provide fast service for any kind of inspections.

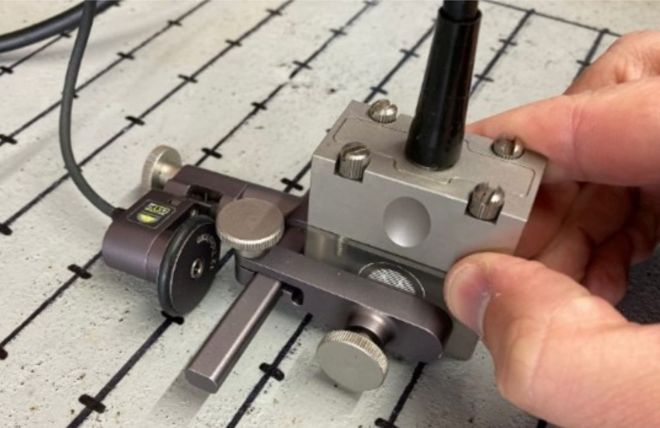

The Veo3 is a general-purpose instrument. It could fit in every industry requiring NDT inspections. Historically, the Veo platform performed incredibly well with the WheelProbe2; it became, in many markets, the reference for composite and corrosion assessment.

The service companies providing TFMi imaging would now be able to provide high shape coherent weld imaging. That benefit is a unique selling point in terms of service offering. Hence, better inspection results can catch more potential customers.