Maritime Shipping Industries

Maritime transportation is a vital component of global trade and is responsible for delivering over 80% of goods worldwide.

Ships are essential for transporting goods across oceans and seas, connecting countries, and supporting global economic growth. With the importance of this trade, the safety and reliability of these vessels and their crews are the number-one priority.

Non-destructive testing (NDT) techniques are widely used in shipbuilding to inspect materials and components during construction, and in periodic in-service inspections throughout the life of a ship to ensure the reliability and safety of the ship is maintained at a high level.

1. Inspection Targets

- Weld Inspection: Ultrasonic inspection of welds can detect cracking, porosity and lack of fusion defects that may affect the integrity of the weld and compromise component safety.

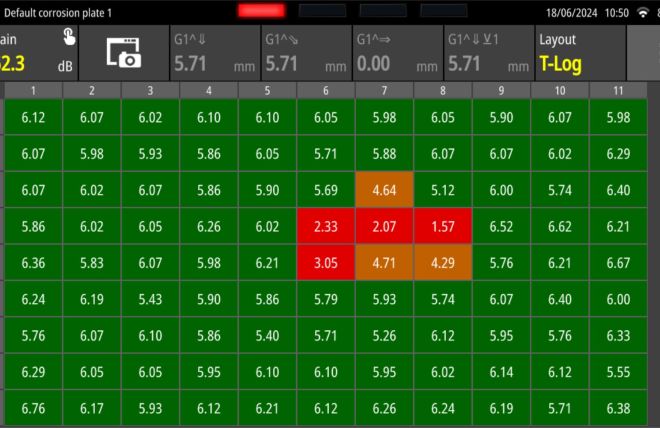

- Structural plate/component Inspection: Inspection of beams, girders, and inner Hull plating can detect corrosion and pitting, which can weaken structures.

- Machinery and Equipment: Engines, generators, pipework and other machinery are inspected for wear, corrosion and damage.

- Hull and Deck Structure: Inspected for corrosion, damage and fatigue-related issues that can compromise vessel strength and integrity.

2. Challenges

- Limited Access: Some areas of a ship are very difficult to access once in service, these may require automated scanners or confined space entries to get to the inspection locations.

- Large surface areas: Hull inspections require 100% coverage, which is a very large area to cover; this can be covered by multiple teams working together or automated scanners covering the ship in segments.

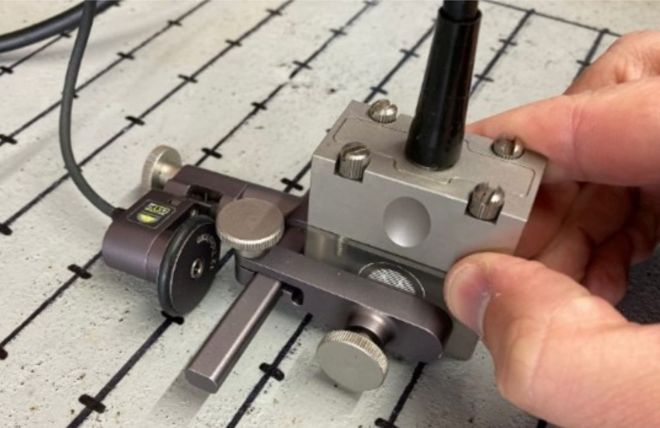

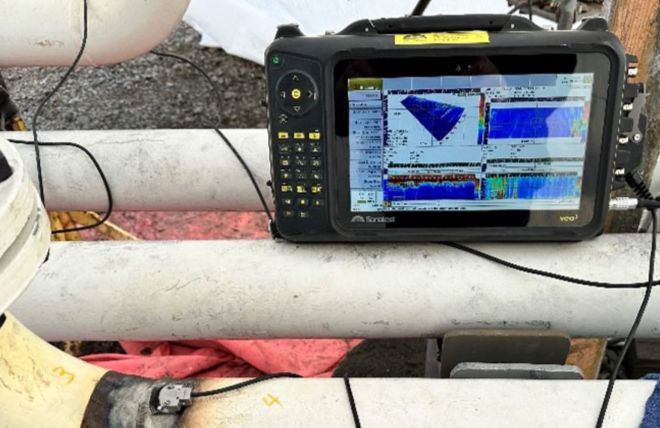

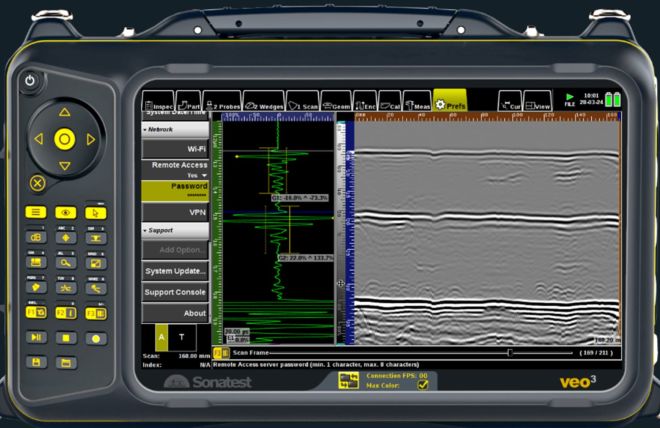

.Sonatest provides a range of ultrasonic solutions for shipping inspections, The VEO3 and RSFlite provide phased array corrosion mapping capabilities, compatible with automatic inspection crawlers. The VEO3 also includes PA weld inspection, TFM TFMi and TOFD inspection methods.

The Wave offers the most advanced conventional flaw detector in the world, with CAD-imported interactive scan plans and a host of tools and applications; this set is now the standard for conventional UT.

We also supply Carestream radiographic equipment, including digital imaging systems used in maritime shipping applications.

Frequently Asked Questions

Ultrasonic inspection plays a critical role in ensuring the safety and longevity of maritime vessels. It effectively detects internal and surface anomalies such as cracks, corrosion, and welding defects in the ship's structure. a ship is constructed of large parts which require complex welding solutions, and the reliability of this massive asset requires NDT control for both its construction and its maintenance.

Phased array technology enhances maritime inspections by increasing the productivity of inspectors, giving more flexibility in for differing applications and providing permanent data files for long term tracking of assets. Phased array can inspect a wide range of welding applications. This flexibility provides comprehensive coverage of complex geometries and delivers detailed images of internal structures, improving defect detection and characterisation over traditional methods.

Sonatest equipment is designed to overcome various maritime inspection challenges including limited access and the need to cover large areas efficiently. Our solutions, such as the VEO3 and RSFlite, offer phased array corrosion mapping and are compatible with automatic inspection crawlers for enhanced accessibility and thorough coverage. They can also be VPN connected over the internet, the possibility to remote support costumers in offshore situations is a big advantage.