- Application Notes

TFM and TFMi for Butt Weld Inspection and Defect Characterisation

The introduction of Full Matrix Capture (FMC) data acquisition and Total Focusing Method (TFM) has significantly elevated the capabilities of phased array inspections, and with the standardisation of FMC/TFM in butt weld inspection within ASME and ISO standards, it is adopted across many industries.

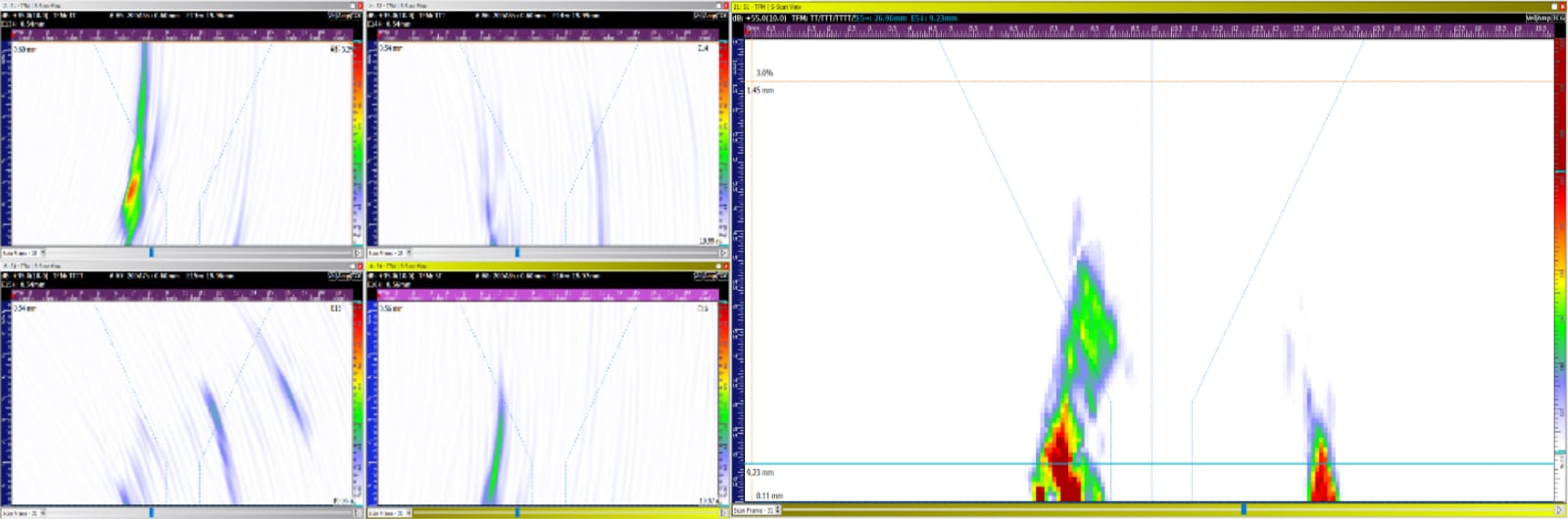

Total Focusing Method Intermodal (TFMi™) was developed in partnership with Holloway NDT and introduced on the VEO3, this allows for the combining of up to four propagation modes into a single acquisition window and provides a high fidelity image of defects to aid in characterisation and sizing.

Fig. 1 - Root crack defect shown In TFM scans on the left and TFMi™ on the right

Advantages

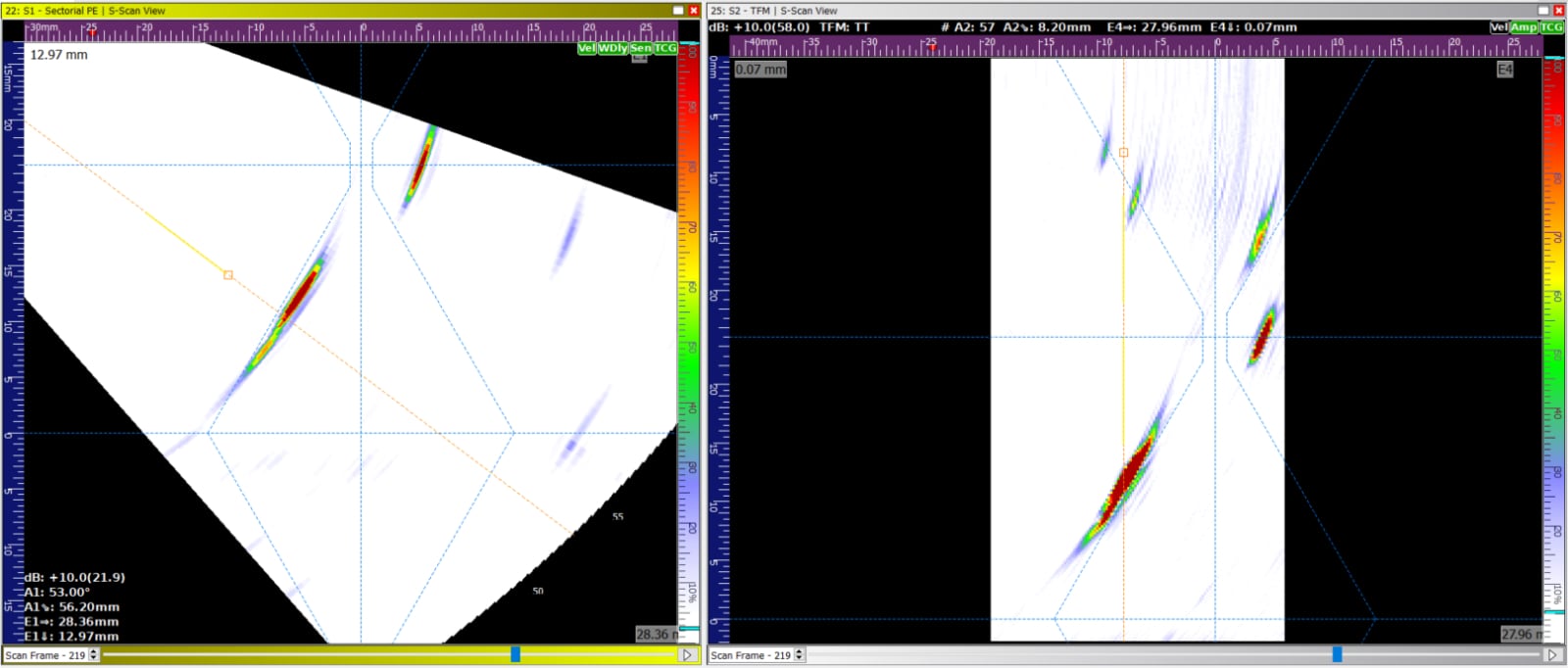

The VEO3 can freely run PA, TFM and TFMi in the same scan with any combination of up to 8 of the following, 6 TFM, 1 TFMi™ and 8 PA groups. That creates a rich insightful layout of usual S-scan side view and the latest TFM imaging at the same time.

Having both PA and TFM in the same scans save time where other systems may need to do these scans separately.

The high fidelity images gained from TFM and TFMi™ can aid in defect sizing and classification, this data can also be used to track defect growth more accurately over repeated inspections.

Fig. 2 - PA and TFM data gathered in the same scan, tip diffractions can be seen in the TFM image

Challenges and solutions

Some well know challenges with using TFM are large file sizes and slower scanning speeds due to the large data acquisition tasks being undertaken.

The VEO3 software is designed with scanning speed in mind and provides one of the highest scanning speeds on the market, but other tools are provided to help dial in your TFM sensitivity without losing productivity.

- Sparse Matrix Capture (SMC) modes are available which lower the number of elements used to gather the data and speed up acquisition.

- Data file sizes are unlimited on the VEO3 meaning you do not have to split up long scans into smaller chunks, you can just keep on scanning up to the 128GB SSD hard drive size!

- Full control over the TFM screen resolution allows for fine tuning to get the best out of the image whilst saving data.

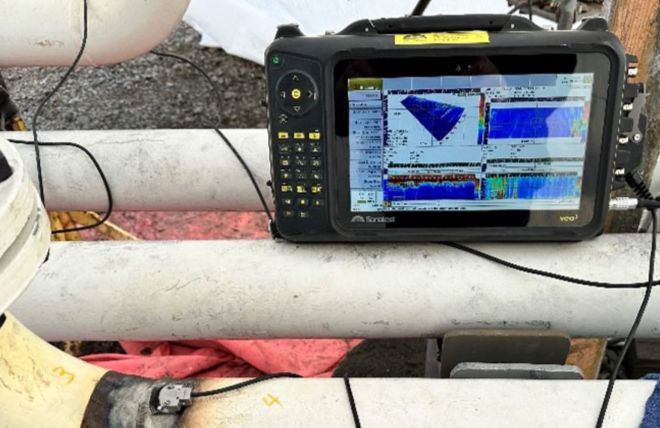

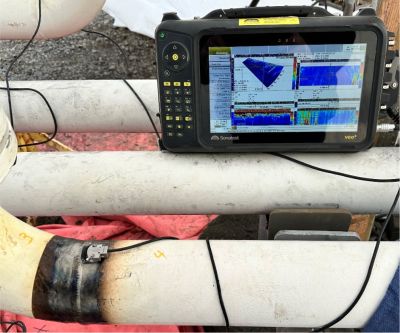

Fig 3 - PA and TFM scan on a pipe to bend butt weld

Conclusion

The VEO3 provides a full butt weld PA inspection package with simultaneous PA, TFM and TFMi™ scanning capabilities. While also being designed for high scanning speeds, productivity will not be sacrificed quality of data, and with the increased defect detection and classification offered by TFM/TFMi™ you can inspect with confidence.

Recommended Tool Package

| Category | Links to our website |

|---|---|

| Acquisition Unit | The VEO3 PAUT Flaw Detector details can be found here. sonatest.com/products/flaw-detectors-phased-array/veo3 |

| Transducer | Our PAUT transducer and wedges list and catalogue can be found here sonatest.com/products/phased-array |

| Calibration Block | Our calibration block list can be found here sonatest.com/products/calibration-blocks |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education