Military Sector

The military and defence sector operates throughout the world in the most hostile environments - and equipment is operating at the limits of performance. Non-destructive Testing (NDT) equipment must also be up to the task of operating in these environments for use in the field.

NDT plays a crucial role in the military by ensuring the safety and reliability of equipment. Structures are often being deployed to very harsh environments. Military applications can fall under aerospace (fighter jets, cargo aircraft), Maritime shipping (aircraft carriers, submarines, battleships) , automotive (tanks, off-road vehicles, mobile launch platforms), temporary and permanent structures (bridges, towers), to mention a few.

1. Inspection Goals

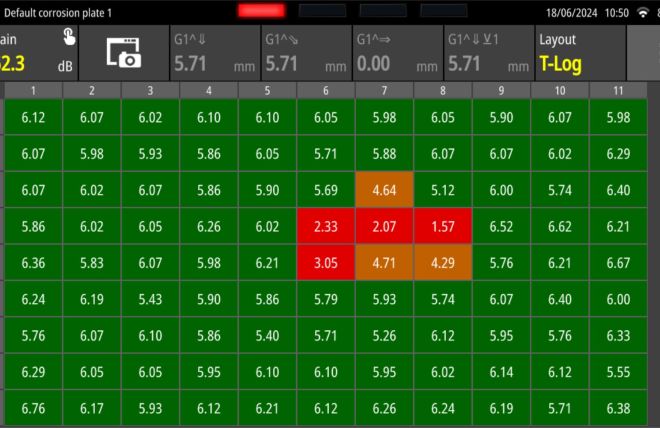

- Ensure the safety and operational capability of equipment: Equipment may remain unused for long periods of time; inspection ensures that the equipment is operational and safe to use when required.

- Identify flaws: locate and analyse flaws early to allow for repair or replacement before the equipment gets to the field.

2. Challenges

- Harsh environments: Equipment needs to operate in very harsh environments, from high heat, high humidity to cold and dry. Equipment must perform equally in all environments in which the military operates.

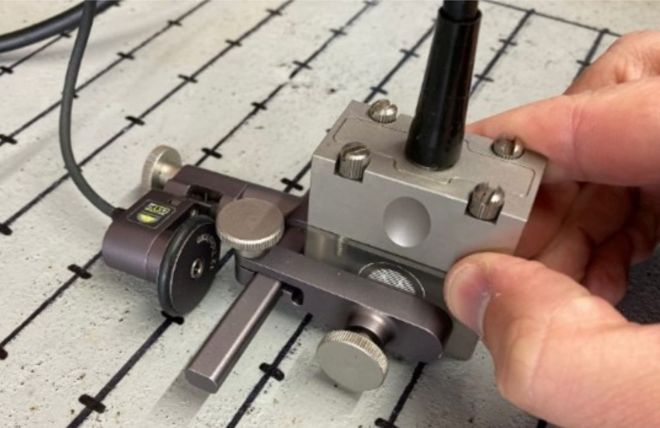

- Complex geometry parts: Structural parts, composite sections, and vehicle shielding can all be unconventional shapes, making inspection a highly skilled task for operators.

- Advanced Materials: new and advanced materials used in the military such as special steels, coatings and composites can pose inspection challenges that require specialised equipment and procedures to assess.

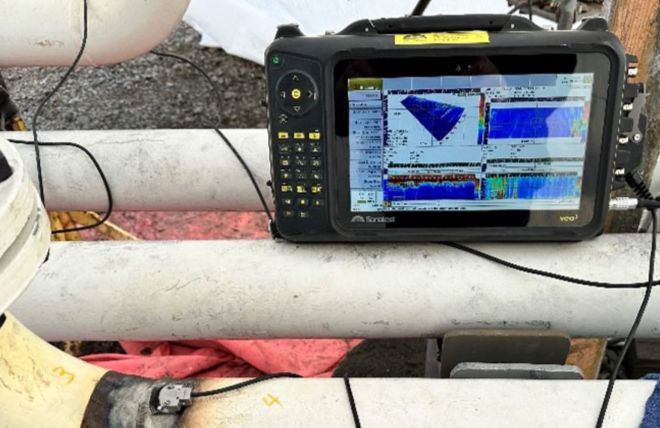

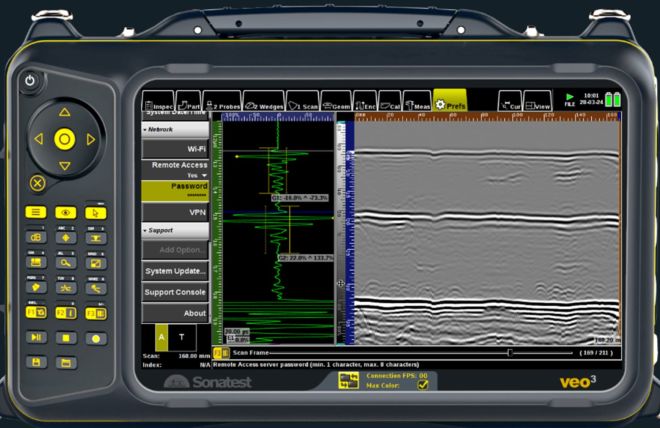

Sonatest offers a range of ultrasonic and radiographic solutions for use in military applications. The VEO3 offers the advanced ultrasonic methods phased array, TOFD, TFM and TFMi, which are utilised in the aerospace, naval, automotive and structural applications throughout the defence sector.

The Wave offers the most advanced conventional flaw detector in the world, with CAD-imported interactive scan plans and a host of tools and applications; this set is now the standard for conventional UT.

We also supply Carestream radiographic equipment in the UK region including digital imaging systems used in aerospace applications.

Frequently Asked Questions

Non-destructive Testing (NDT) is vital in the military for ensuring the reliability and operational readiness of equipment deployed in challenging environments. The military requires high quality components, asset integrity and functionality of systems working in harsh temperatures and high stress conditions. Ranging from aerospace to naval and ground vehicles, reducing failure risks in critical situations.

Sonatest provides advanced ultrasonic and radiographic NDT solutions, including the VEO3 and Wave systems, that offer capabilities essential for military specifications. That is why Sonatest designs instruments built to resist to difficult environments of inspection. Our products are dust resistance, vibration tested and survive to temperatures from -10 to 45 degrees. These include high-resolution imaging for aerospace structures, vehicles, and other strategic assets, which allow detailed inspections of complex geometries and advanced materials.

NDT in the military must contend with extreme conditions such as hits and knocks, varying temperatures, and humidity levels. Our equipment features internal shock absorption to protect the electronics, and the casing of the instrument is designed to dissipate heat.

Sonatest offers products such as the VEO3, which supports advanced ultrasonic methods like phased array, TOFD, TFM, and TFMi™ suitable for various military applications. Additionally, the Wave represents the forefront of conventional ultrasonic testing with capabilities that include CAD-imported interactive scan plans, supporting detailed inspections necessary in the defence sector. Our products are compatible with a wide range of transducers usually between 0.5MHz and 20MHz. That bandwidth allows NDT evaluation for typical thick steel parts and the most recent robust composite military innovations that replace steel alloys.