In the oil and gas industry, valve inspections may seem like a small part of the quality assurance process, but they’re vital to maintaining asset integrity. Each valve type (ball, gate, plug, or globe) features a unique geometry that can complicate ultrasonic testing (UT) more than expected.

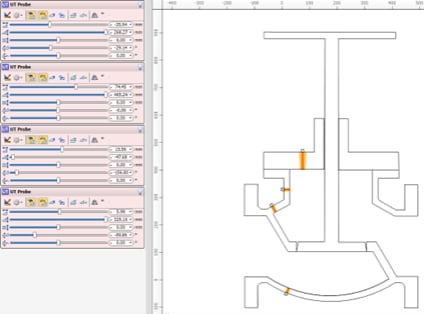

That’s where the Sonatest Wave stands out. The above scan plan will fully match with the inspection strategy.

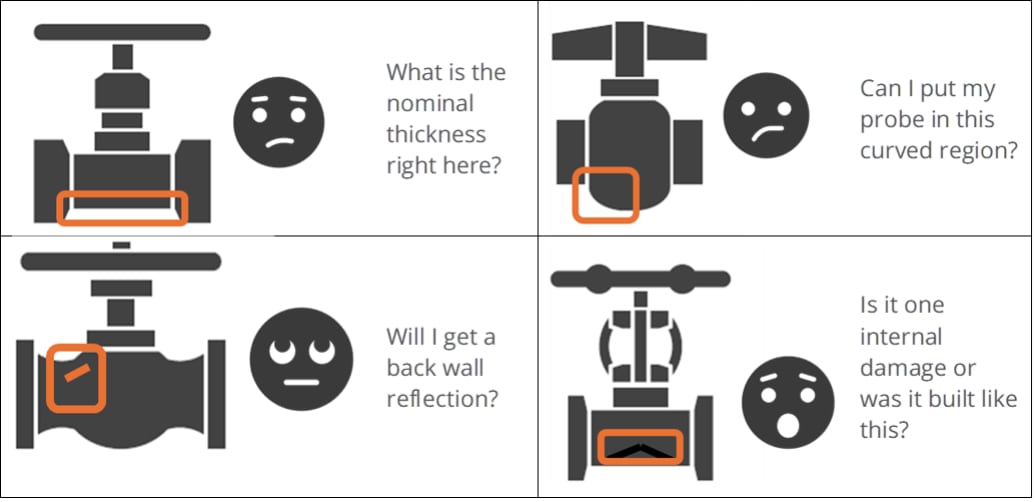

Traditional UT inspections on valves can be challenging due to the complex internal and external designs that are optimized for fluid flow and sealing—not for easy probe positioning. Knowing where to inspect for remaining wall thickness or signs of wear requires more than just experience—it requires the right tools.

The Wave helps eliminate that guesswork above. Our instrument allows inspectors to upload custom valve drawings directly into the device. With real-time A-scan overlay, regions of interest become immediately clear, and technicians can confidently evaluate thickness or damage without missing a beat.

The result? Faster inspections, clearer reporting, and greater confidence in your data.

Whether you're inspecting welds, tracking corrosion or valve flanges, the Sonatest Wave brings simplicity and precision to even the most complex valve geometries.

For further information on our equipment and application notes, follow these links:

News Filter...

The latest news from Sonatest direct to your inbox.

Tags