- Application Notes

Flange Inspection PAUT

Flanges are found everywhere in industry, they are the main form of connecting pipeline lengths to other pipes, valves, vessels etc. They are often exposed to corrosive fluids and challenging environments that can cause damage over time, potentially leading to failure. Accordingly, it is vital that any degradation is identified during inspections to maintain the asset and avoid leakage or catastrophic failure.

Visual inspection is a common method for inspecting flanges but this means having to shut down the plant and open the flanges which costs time and money. Phased array allows the inspection of flanges, in service, without having to take them apart, resulting in quicker and lower cost inspections.

Fig. 1 - Flange face defects

Inspection information:

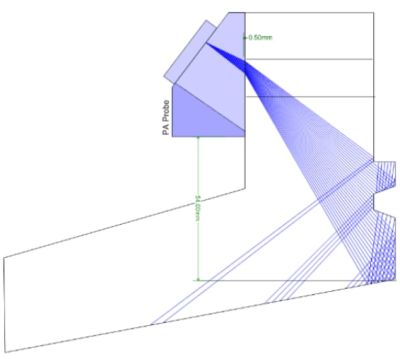

The inspection was performed from the bolt face as shown in the image below, this will be an accessible face with space between bolts for the scans.

Fig. 2 - Scan plan used for the inspection trial

- A 5MHz, 32 element PAUT transducer was used for this inspection, smaller probes may also be used to get a greater amount of coverage

- For best results the inspection should be encoded, specific scanners can also be used when applicable

- Between 50% and 70% coverage of the flange face is achievable when inspecting from the bolt face

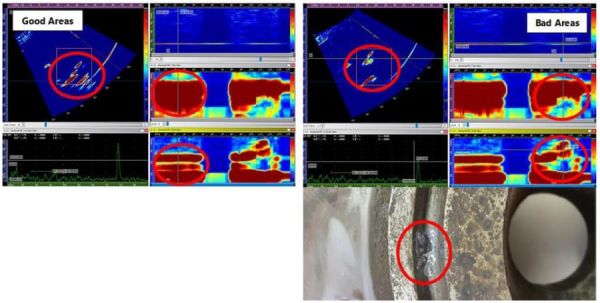

- The flange being inspected has a grove for the gasket (can be seen in above image) this can be suspectable to corrosion and pitting, images below show results of inspection on this area:

Fig. 3 - Scans of a flange face showing ‘good’ and ‘bad’ / defective areas

When detecting defects on the flange face the extractor box position is moved so that it cover between the grove and the inside corner of the flange, the image below shows full Top view as well as the S-Scan view looking at a good area.

Fig. 4 - Scan acquisition layout

Fig. 5 - Showing detected defect as seen in the right image

Fig. 6 - Showing detected defect as seen in the right image

Conclusion

Phased array has shown to be an efficient and fast way to inspect flange faces. By using the Veo3, quick easy reporting is available at a touch of a button, with also the capability to insert specific logos and project information etc.

Full coverage of the flange face is not possible using this method as some area will be blocked by the bolt holes however sufficient is provided to confirm that the flange is sound or identify a problem which may then require further investigation.

Further research is going to be completed using FMC, this will appear on a separate application note.

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | VEO3 phased array data acquisition unit | |

| Probe | D1A 5M32E probe and D1AW N60S wedge | |

| Encoder | AXYS Encoder |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products