- Blog

UT of Composites: Understanding the Physics Behind Inspection

9th February 2026

Will Haworth, Sonatest

Composite materials are now essential to aerospace design, used in fuselage skins, wing panels, fairings, ducts, and control surfaces. Their high strength-to-weight ratio, fatigue resistance, and corrosion tolerance make them ideal for flight, but inspecting them demands a different approach than for traditional metal structures.

This blog covers the basics of ultrasonic testing (UT) for composite materials, showing how wave behaviour shifts, which techniques are most effective, and what tools help spot internal flaws like delaminations, disbonds, porosity, and FOD.

Why Composite Materials Are Challenging to Inspect

Ultrasonic waves act differently in composites compared to metals because of their anisotropic and layered structure. Sound energy may scatter, reflect, or be absorbed in unpredictable ways.

Common acoustic behaviors in composites include:

- Attenuation – Signal energy is lost due to resin absorption and ply interfaces

- Anisotropy – Wave velocity varies with fiber orientation

- Scattering – Ply boundaries or resin pockets distort beam paths

- Reflection and/or Transmission – Internal boundaries (like bond lines) can split or reflect energy

These effects complicate flaw detection, making conventional A-Scan evaluation alone insufficient in most cases.

Typical Composite Flaws Detected with UT

Ultrasonic inspection in aerospace composites focuses on detecting:

- Delaminations – Separation between laminate plies

- Disbonds – Failed adhesion between core and skins in sandwich panels

- BVID (Barely Visible Impact Damage) – Internal damage not evident on the surface

- Porosity – Entrapped gas or incomplete wet-out during layup

- FOD (Foreign Object Debris) – Trapped objects or material inclusions

These flaws affect sound transmission differently and may present as diffuse reflections, energy loss zones, or phase distortions in UT signals.

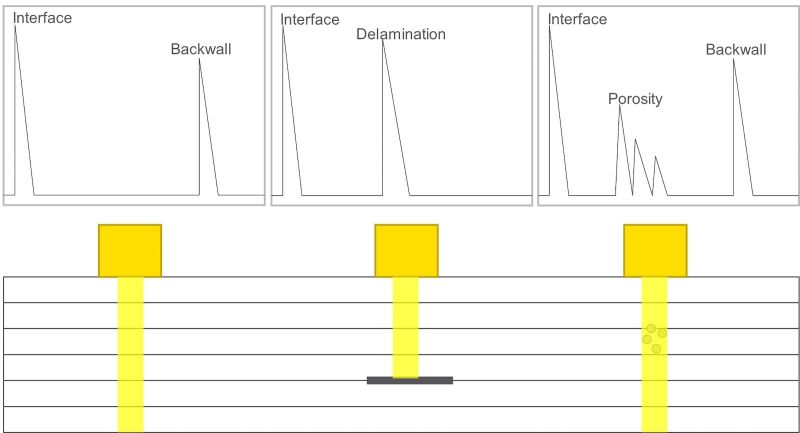

How Echoes Are Used to Detect Flaws

Ultrasonic flaw detection relies on analyzing how echoes return to the probe. In composite materials:

- A sharp, high-amplitude echo at a known depth may indicate a delamination or disbond

- A loss of backwall signal may suggest a large area of attenuation from porosity or trapped FOD

- An echo arriving earlier or later than expected could indicate thickness variation or ply dropout

- Reflections within the material before the backwall are often signs of layered defects

In many cases, flaw interpretation requires scanning to compare signal behavior across an area and using imaging tools for confirmation.

Choosing the Right Ultrasonic Setup

The effectiveness of inspections depends heavily on the type of probe, interface, and technique used. Selection factors include material type, part geometry, and defect location.

Conventional vs Phased Array Probes

- Conventional UT (single-element): Suitable for thickness checks or basic flaw detection

- Phased Array (PAUT): Enables electronic scanning, focal control, and image generation for improved coverage and characterization

Scan Mode

- Linear scanning is preferred in aerospace composites. It preserves beam orientation and avoids issues associated with beam angle variation in anisotropic materials.

Couplant Type

- Water is the most common couplant in aerospace applications, offering excellent transmission and consistent surface conformity

Delay Lines and Matching Layers

- Delay lines improve near-surface resolution and protect the probe face, especially on rough surfaces

- Rubber or water delays also help with impedance matching and enable smoother scanning on curved parts during encoded inspection

Contact vs Immersion Inspections

- Contact inspection is simple and portable, but can be limited by part geometry and surface condition

- Immersion inspection offers full coupling and uniform pressure, ideal for complex surfaces, but requires a tank, gantry system, and setup time

- WheelProbes offer a hybrid solution: nearly dry coupled rolling with water-filled interfaces, combining immersion-level coupling with contact-level convenience

Interpreting Scan Views

Advanced inspections often rely on more than just A-Scan data. Key views include:

- C-Scan – Provides a top-down map of amplitude or time-of-flight, ideal for flaw detection, mapping, and sizing

- B-Scan – Cross-sectional view along a scan line showing part thickness and flaw depth

- A-Scan – Still used for depth confirmation, signal interpretation, and gain calibration

In composite inspections, C-Scans are especially valuable for revealing subtle flaws, such as disbonds close to surfaces or porosity, that may not be clearly distinguishable in an A-Scan alone.

Aerospace Applications

Ultrasonic techniques are used in many aerospace composite inspections, including:

- Delamination detection in carbon fiber skins

- Bond integrity checks in honeycomb or foam core structures

- FOD and porosity location in composite layups

- Impact damage assessment in flight control surfaces

- Flaw mapping and documentation for composite repairs or manufacturing QC

- Curved part inspection on ducts, fairings, or tight-radius frames

Each of these applications benefits from tailored probe setups, imaging tools, and knowledge of how UT waves behave in the target structure.

Conclusion

Ultrasonic inspection of aerospace composites is a highly specialized process that requires understanding the unique physics of sound wave behavior in layered, anisotropic materials. When approached correctly, with the right probes, scanning techniques, and image analysis, UT provides a powerful method for non-destructively evaluating the structural health of modern aircraft components.

In future blogs, we’ll apply these principles to specific aerospace inspection challenges, starting with delamination detection in carbon fiber skins.

Please contact our Sales Team if you have any questions. You can also find more solutions on our website.

To follow further content and our newsletter, please contact us and check “Add to mailing list”.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags