A 'fixed' cone/dome roof on a storage tank is a crucial aspect for the safe containment of the product. Although appearing to only be a cap, the roof is designed to stringent standards to cope with multiple safety points for the tank.

Safety points include:

- Contains gases within the vapor space of the tank and copes with internal pressures and potential vacuum loads

- Manages external loads from rain, snow, and wind

- Be safe for personnel to work on the roof plates for taking samples or accessing gauges

- In overpressure situations, allow specified welds to break safely to release dangerous pressure, breaking on the roof rather than the shell or floor

Because of these points and more, the fixed roof of the tank is thoroughly inspected regularly.

Thickness survey and T-Logging

The most basic form of inspection for determining the roof plate thickness is ultrasonic testing (UT). Conducting the inspection with thickness gauges or flaw detectors, the inspector uses a UT transducer on the plate surface to obtain a live thickness reading from the contact point.

Uses:

- Spot readings at specific locations on the roof are defined by standards

- Area scanning for small locations to define corrosion patch dimensions

- Thickness measurements on nozzle attachments and pipework

For further information on our equipment and application notes, follow these links:

UT equipment, Thickness Gauges, Application notes

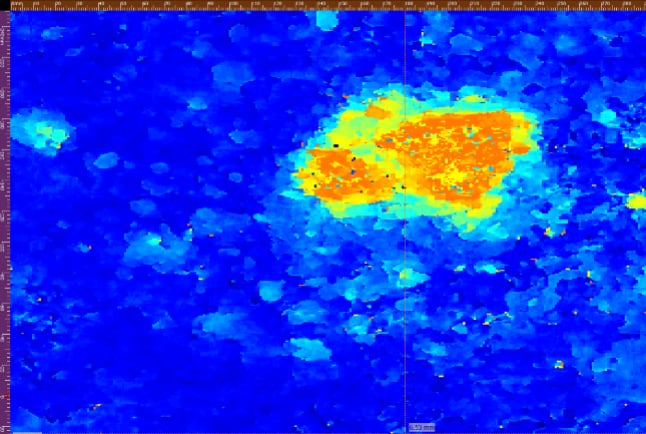

Corrosion Mapping

When detailed coverage of large plate areas is required, UT/ phased array (PA) corrosion mapping offers an ideal solution.

Conducted manually in specific areas or automated by scanners that can access restricted zones outside of walkways, it is capable of quickly recording thickness data and presenting this information as a visual map that clearly details any wall loss areas.

The data file also presents a permanent record of the condition of the area, on repeated inspections the corrosion area corrosion growth during repeated inspections.

Uses:

- Detecting and monitoring crevice corrosion and contact point corrosion from internal support structures

- Establishing baseline condition maps of the roof plates

For further information on our equipment and application notes, follow these links:

Phased Array equipment, Scanners, Application notes

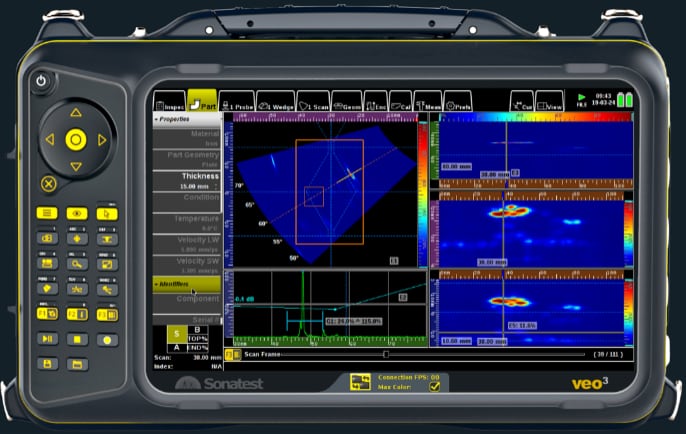

Weld Inspection

Various types of welds exist on a tank roof, including butt welds, lap welds, nozzle welds, and stitch welds.

Normally, a defined percentage of overall welds is inspected at manufacture to give confidence in the overall weld quality. Other occasions for inspection are for repair or routine checks.

Manual UT, phased array, ToFD, TFM, and TFMiTM are all methods that can be used to inspect welds and detect original welding defects or those that have developed over the tank's life.

Sonatest provide advanced equipment, transducers and scanners to carry out weld inspections in all configurations and situations.

For further information on our equipment and application notes, follow these links:

Phased Array equipment, Scanners, Application notes

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags