- Application Notes

Wind Turbine Bolt Inspection Utilising Ultrasonic Phased Arrays

Bolts are vital for the long and safe running of wind turbines both on and offshore, they can be found in multiple areas within the Nacelle as well as ancillary structures. Here we carry out ultrasonic phased array inspection of two main types of bolts in a turbine with induced defects and show the results.

In-service bolts can fail for multiple reasons, the primary failure mechanism we aim to detect in these bolts are cracking defects located anywhere in the bolt, these are most likely to appear at high stress points e.g. contact points with the threaded bolt or the item being joined.

Traditionally bolts are either replaced after a set time period regardless of their condition, or removed and visually inspected for their integrity, this is both expensive and time consuming and generally requires the turbine to be shut down or run at reduced capacity.

By utilising the Veo3, bolts can be quickly and accurately inspected without the need for them to be removed. This data can be recorded and used in remaining life calculations, this allows the asset owner to better plan for the future of the turbine and continue to run at capacity saving time and money.

The probe frequency and element count can be selected on a case by case basis to ensure the best resolution against penetrating power for differing bolt sizes.

Inspection Aims

For this trial we used 2 turbine bolt types with induced cracks and notches to simulate defects:

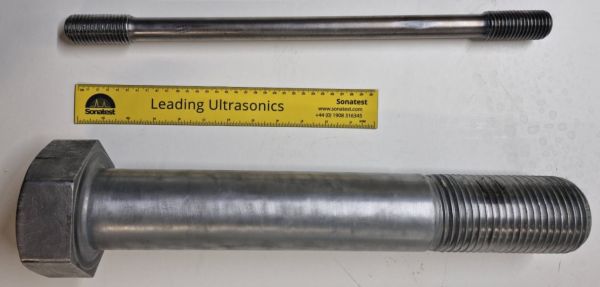

- Tower flange connection bolt, 500mm long x 70mm (see Fig. 1)

- Turbine blade bolt, 480mm long x 25mm (see Fig. 1)

Within the Tower Flange bolt there were 6 induced defects (1 notch and 2 cracks in the threaded area and 1 notch and 2 cracks in the shaft of the bolt).

Within the Blade Bolt there were 4 induced defects (1 notch and 1 crack in each of the two threaded areas).

Fig. 1 - Bolts under inspection

Inspection Procedure:

- The inspection was carried out from the “threaded” end of the tower flange bolt and the datum end of the blade bolt

- The data was collected with an encoded scanner for the full circumference and a 10% overlap

- Sonagel couplant was used as the coupling medium

Inspection Setup:

Equipment

- System – Veo3 32:128

- Probe - X2B-5M32E with a side entry cable

- Scanner – Creo Bolt Scanner with large cradle with offset probe holding plate and small probe cradle setup

- Couplant – Water / Sonagel

Fig. 2 - Probe and scanner positioned on the bolts

Scan Setup:

Tower Flange Bolt

- Longitudinal sectorial scans

- 0° - 30°, 0.5° resolution and 0mm - 250mm scan length

- 0° - 15°, 0.5°resolution and 200mm - 500mm scan length

- Focusing set to “Natural”

Turbine Blade Bolt

- Longitudinal sectorial scans

- Top threads +30° - 30°, 0.5° resolution and 0mm - 100mm scan length

- Shaft +10° - 10°, 0.5° resolution and 0mm - 100mm scan length

- Bottom threads +5° - 5°, 0.5°resolution and 390mm - 100 scan length

- Focusing set to “Natural”

Results

Tower Flange Bolt

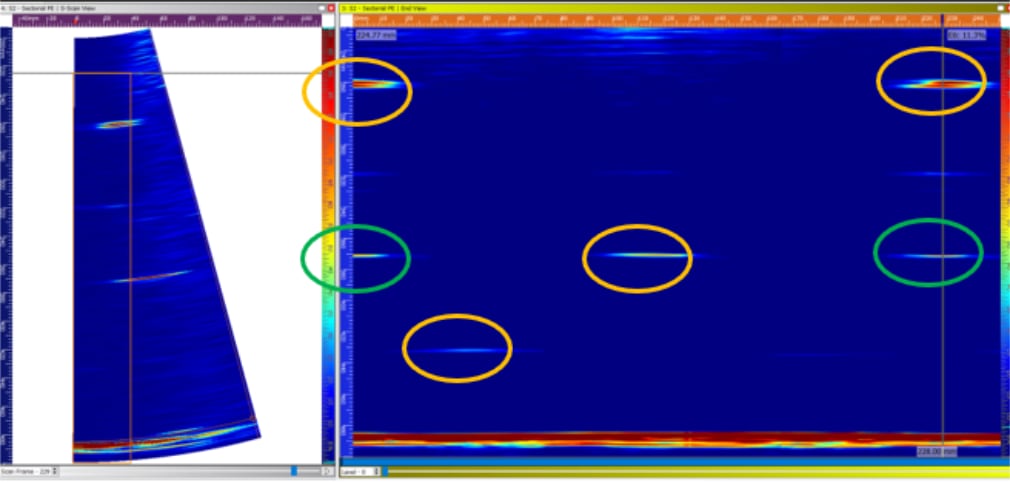

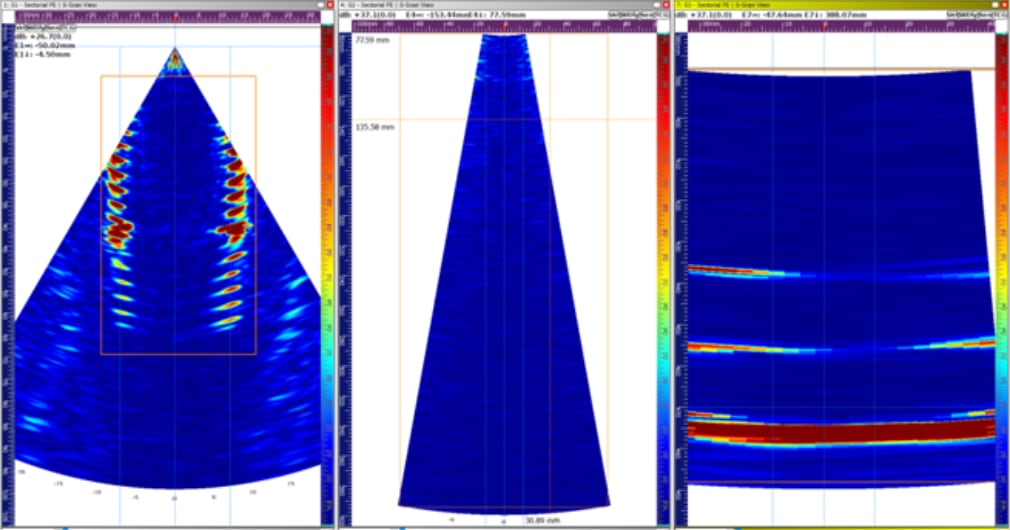

All 6 defects were successfully detected using both the S-scan and End view scans. Depths and estimates of surface length can be made (See Figures 3-5)

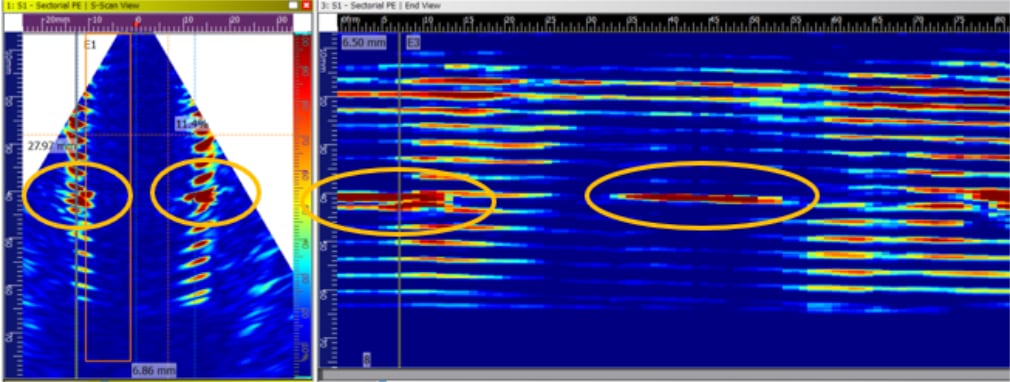

Turbine Bolt

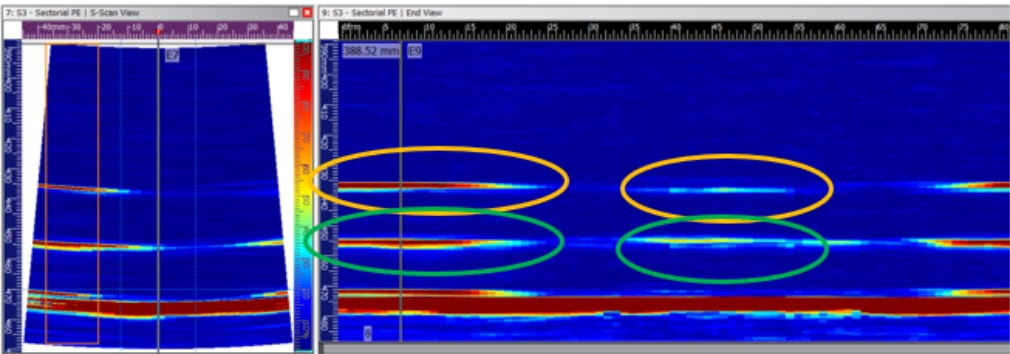

All 4 defects were successfully detected using both the S-scan and End view scans. Depths and estimates of surface length can be made (See Figures 6-8)

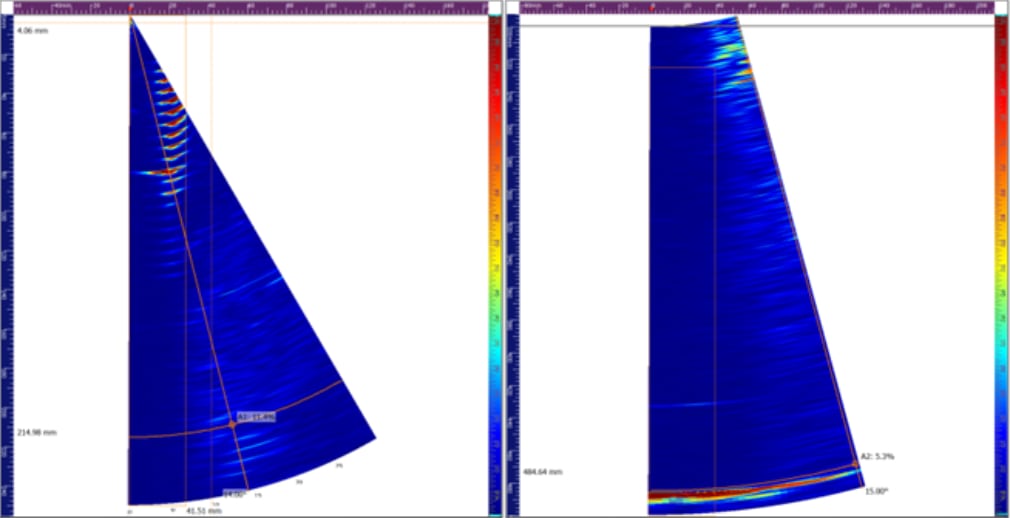

Fig. 3 - Tower Flange Bolt S-Scan setup

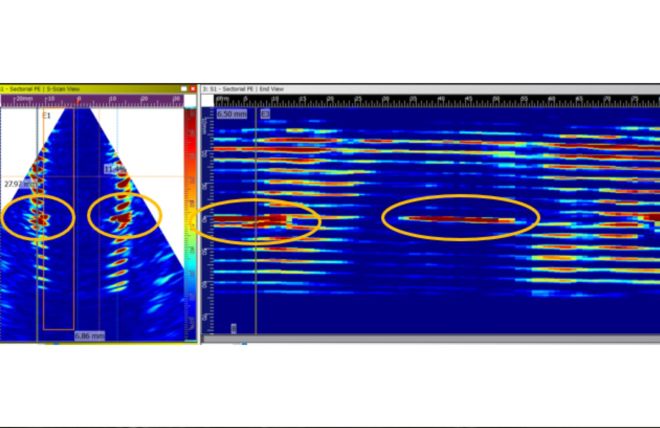

Fig. 4 - Tower Flange thread defects

Fig. 5 - Tower Flange Bolt defects (repeat echoes circled in green)

Fig. 6 - Turbine Bolt S-Scan setup

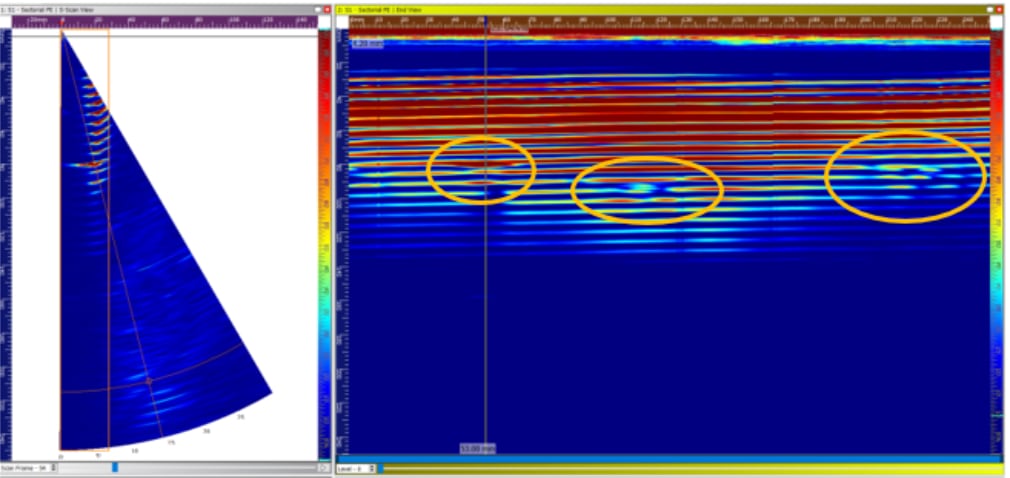

Fig. 7 - Turbine Bolt upper thread area defects

Fig. 8 - Turbine Bolt upper thread area defects (repeat echoes circled in green)

Conclusion

- Phased array bolt inspection is a quick and efficient way to perform in-service inspection of turbine bolts

- Bolts can be scanned free hand for a quick assessment of the bolt

- Encoding the inspection data helps in the identification of defects and can be used as a permanent record for future inspections of the bolts

- TFM/FMC can be utilised to give better accuracy in defect sizing if required

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education