- Application Notes

Steel Reinforced Conveyor Belt Inspection PAUT

Conveyor belts are widely used throughout the world in many industries and are a vital part of industrial processes. Damage to a belt can cause unplanned shutdowns which revenue losses due to the downtime and repair of the belt.

Non-Destructive testing of the belt can reveal early signs of defects that may result in a failure of the belt in service, this would allow for planned shutdowns and repairs of the belt, mitigating any unplanned downtime and revenue losses.

Fig. 1 - Mining conveyor belts

Issue

Following a requirement from a global producer of aluminium to carry out volumetric ultrasonic inspections to their conveyer belts that were nearing its design life Sonatest Ltd were asked to support validation trials to ascertain accurate remaining wall thickness of the belt and condition of the internal galvanised steel cords.

The belts used for the validation were 10mm and 24mm thick with centralised galvanized steel cords.

Conveyor Belt Design

A typical conveyor belt consists of a top and bottom layer and a centralised core that contains the steel cord reinforcements.

Zinc galvanized steel cord

The cords, made up of many wire filaments, are constructed to provide high flexibility, low elongation and permit efficient and high-strength splice designs. The galvanized zinc coating produces a bonding agent between the cord and insulation gum and provides an important barrier against corrosion.

Insulation gum (core rubber)

Insulation gum bonding rubber, which penetrates and adheres to the steel cords. The result is excellent adhesions, corrosion resistance and splice efficiencies.

Top and Bottom cover breakers

The top and bottom covers are designed to protect the steel cord strength member against the abusive environmental conditions prevalent in most conveying applications. Compounds are generally available to withstand abrasion, jagged cutting and gouging, high impact, sub-zero temperatures, moderate heat, hardening effects of ozone attack and fire propagation.

The validation trial enable us to show we could successfully penetrate the conveyer belt and image the backwall and internal cords.

Fig. 2 - Conveyor belts in use

Inspection and Results

An encoded phased array L-Scan was used to scan a 10mm wide x 500mm length of the belt.

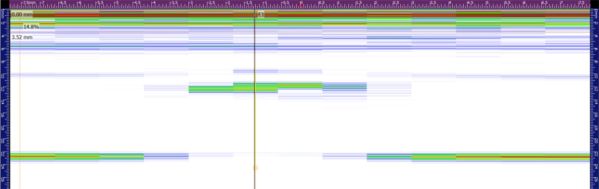

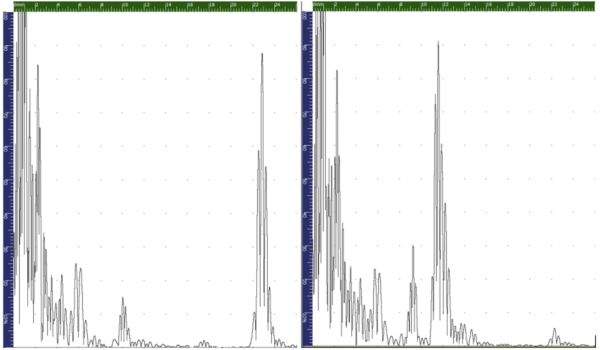

The scan showed the internal cords and the back wall of the belt clearly. (see figs 3-5)

In the 10mm thick belt we were able to identify loss of belt thickness due to wearing on the bottom side of the belt (see fig 6)

Fig. 3 - B-Scan showing the backwall and reinforcement cords

Fig. 4 - L-Scan showing the backwall and reinforcement cords

Fig. 5 - A-Scans showing the response from the backwall (left) and a reinforcement cord (right)

Fig. 6 - B-Scan showing backwall thickness losses due to wearing on the bottom side

Conclusion

The validation proved we can successfully penetrate the conveyer belt, image the internal steel cords to ascertain signs of breakages, image the backwall cover to ascertain wall thickness and signs of wear whilst at the same time collect a permanent record of the data sets collected on site.

Thus allowing for future inspection and monitoring and allow the site engineers to make informed decisions to calculate both current condition of the belt and estimated remaining life. Further detail could be collected by carrying out a merged C-Scan of the belt showing cord locations over a large area.

This method can also be useful in testing repairs and joins in a belt to ensure a good joint.

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | Sonatest Veo3 16:64 PA System | |

| Probe | D1A 2.25Mhz (Used for this application note), multiple probes are available, the specific solution to be reviewed on a case by case basis | |

| Encoder | Axys Encoder |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education