- Solutions

PAUT Inspection Of Nozzles Utilising the VEO3

Used throughout industry, nozzles are found on all vessels connecting them to pipework and ancillary items. Each nozzle is unique being related to the vessel and pipe sizes, thickness, angle, and material. Traditional UT inspection is time consuming, creating a scan plan and then performing the scan using multiple transducers.

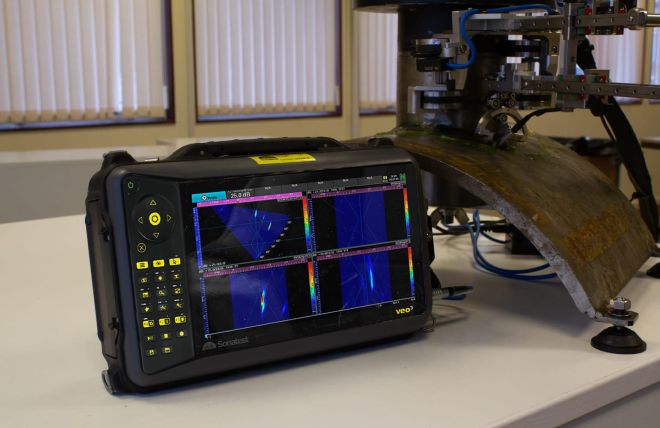

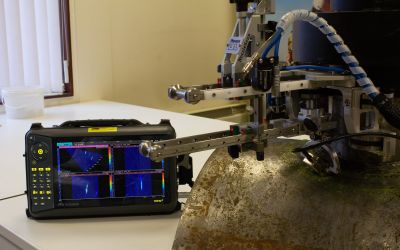

When using the Veo3 and Nozzle Scan the set ups can all be done offsite, thereby substantially reducing, and easing site work. The scanner is placed onto the nozzle with the correct offset and with one pass the inspection is completed. Because there is no need to change to different angled probes, the speed of inspection is significantly quicker, especially when the Nozzle Scan is coupled up with the Veo3, a very fast PAUT unit. The unit is suitable for use on non-ferrous materials. Post analyses can be performed using UT Studio+, giving the technician the ability to easily identify, characterise and size defects. Detailed reports are available automatically.

Fig. 1 - Veo3 and Nozzle scan setup

Advantages:

Veo3

- One of the fastest units on the market, 125 MHz acquisition frequency

- Easy to follow wizard set up process

- Industry best signal to noise ratio

- Ability to create reports direct from the unit itself

Nozzle Scan

- Easy set up

- Speeds up inspection compared to manual methods

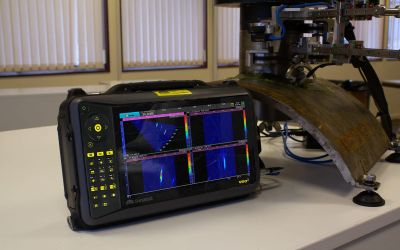

Fig. 2 - Veo3 scan setup

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | Veo3 32:64PR BNC Veo3 32:64PR LEMO | Veo3 32:64 BNC OR LEMO |

| Probe | X2B-001 | 5MHz 32 Element PAUT probe |

| Wedges | X2BW-002 X2BW-003 | N45s wedges N60s Wedge |

| Scanner | N/A | Phoenix 2 AXIS nozzle scan |

| Software | UTStudio+ | Software for all types of analysis |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education