- Software /

Xpair

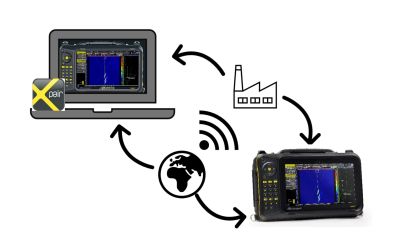

Opening the door to true mobility in the NDT market, Xpair allows a PC based anywhere in the world to access and control Sonatest’s advanced ultrasonic inspection systems

Overview

REACH - COLLABORATE - RESOLVE

Xpair is a PC based software that allows the user to remotely access a PA unit locally on the same network or anywhere in the world with an internet connection.

This access allows the user to view and control all functions on the unit, as well as directly downloading data files to your PC from the unit.

Features

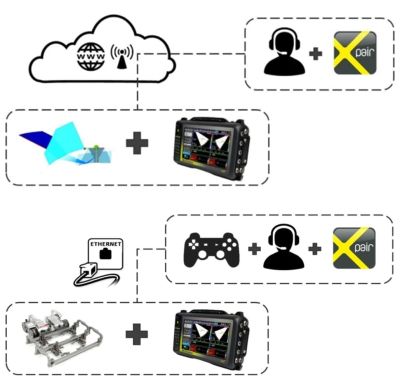

Local Network Connection

Connection to your system locally is simple, all you need is a PC, Xpair software and a Wi-Fi connection.

Local setup: Network connection via Wi-Fi or Ethernet connection to both the system and the PC.

Local Wi-Fi: Router providing network connection via Wi-Fi to both the system and PC.

Wired setup: PC providing an Ethernet connection to the system directly.

Long Distance “Cloud” Connection

Long distance connection to your system requires only a Wi-Fi connection and the Xpair Cloud upgrade to your system.

All you need is a stable Wi-Fi connection on your PC and your system to connect, this can be from a router or even using your mobile phone shared hotspot!

Support and review from anywhere

This innovation gives users the ability to remotely access their instruments from anywhere around the world to...

- Assist real time technician in the field

- Take control of all the instrument functionalities

- Download data for in-depth analysis in the office

- Upload specific setup files to the field technician

- Upload procedures (PDF) to the field technician

Requirements for Xpair

Xpair is compatible with the Sonatest Veo3, VEO+, Prisma and RSFlite systems. Below we detail the specific system software requirements for local and long distance connectivity.

| Connectivity type | Required Software |

|---|---|

| Local Network Connection | PC – Xpair software Instrument – Any up to date Sonatest AP instrument (Wi-Fi connection requires Wi-Fi upgrade and dongle) |

| Long Distance Connection | PC – Xpair software Instrument – XPair Cloud Option installed |

Xpair Options

| Part Number | Item Description |

|---|---|

| Xpair | Xpair PC – General local or remote connection purposes |

| SW-PRISMA-CLOUD | Prisma cloud software key for remote connection |

| SW-RSFLITE-CLOUD | RSflite cloud software key for remote connection |

| SW-veo+-CLOUD | Veo+ cloud software key for remote connection |

| SW-veo3-CLOUD | Veo3 cloud software key for remote connection |