A high-resolution ultrasonic NDT solution speeding up the quality control process of large surfaces.

Linear scanning, also known as electronic scanning, is a type of ultrasonic testing (UT) technique. Applied generally at 0º, this UT technique is recognised to be the best non-destructive testing (NDT) solution to examine the volume inside a majority of structures on the market. Per example, this approach is suitable for composite material inspection and general corrosion mapping.

How does it work?

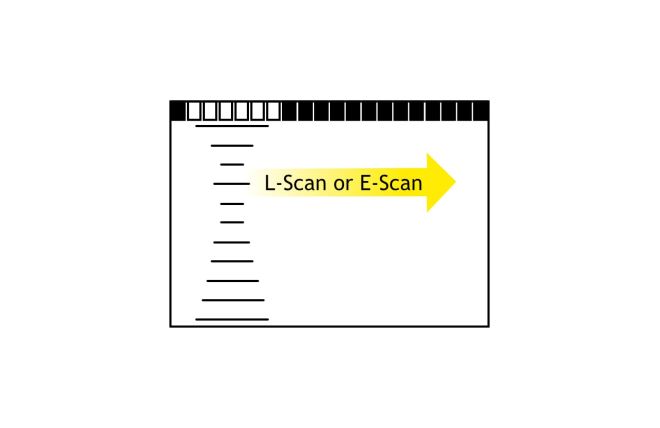

It is all based on the use of a linear array (or probe or transducer), that has many piezoelectric elements in an individual housing. Indeed, each group of elements pulses a single straight beam, at 0 degree. This means that the beams are perpendicular to the inspected surface.

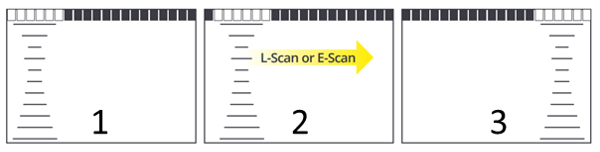

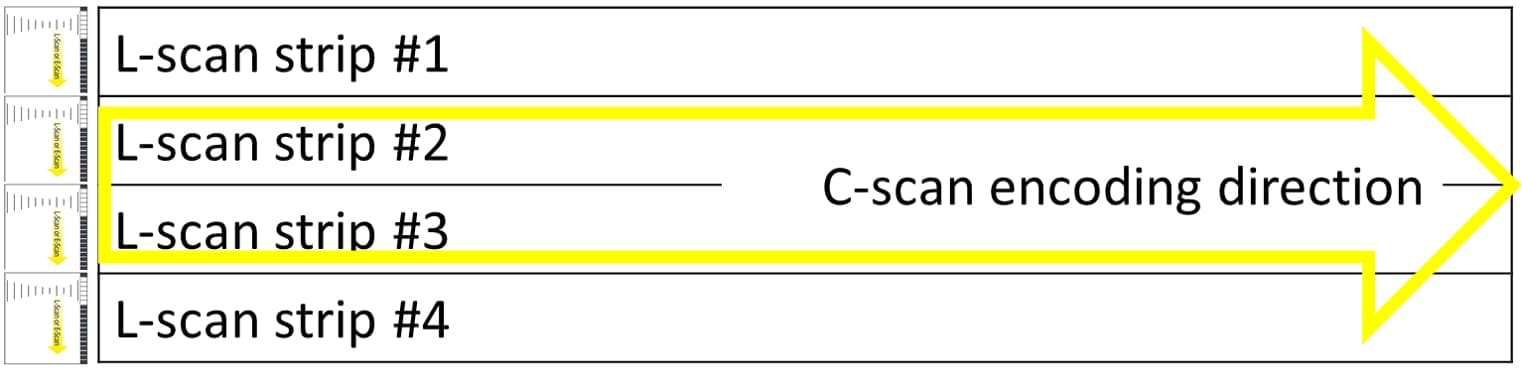

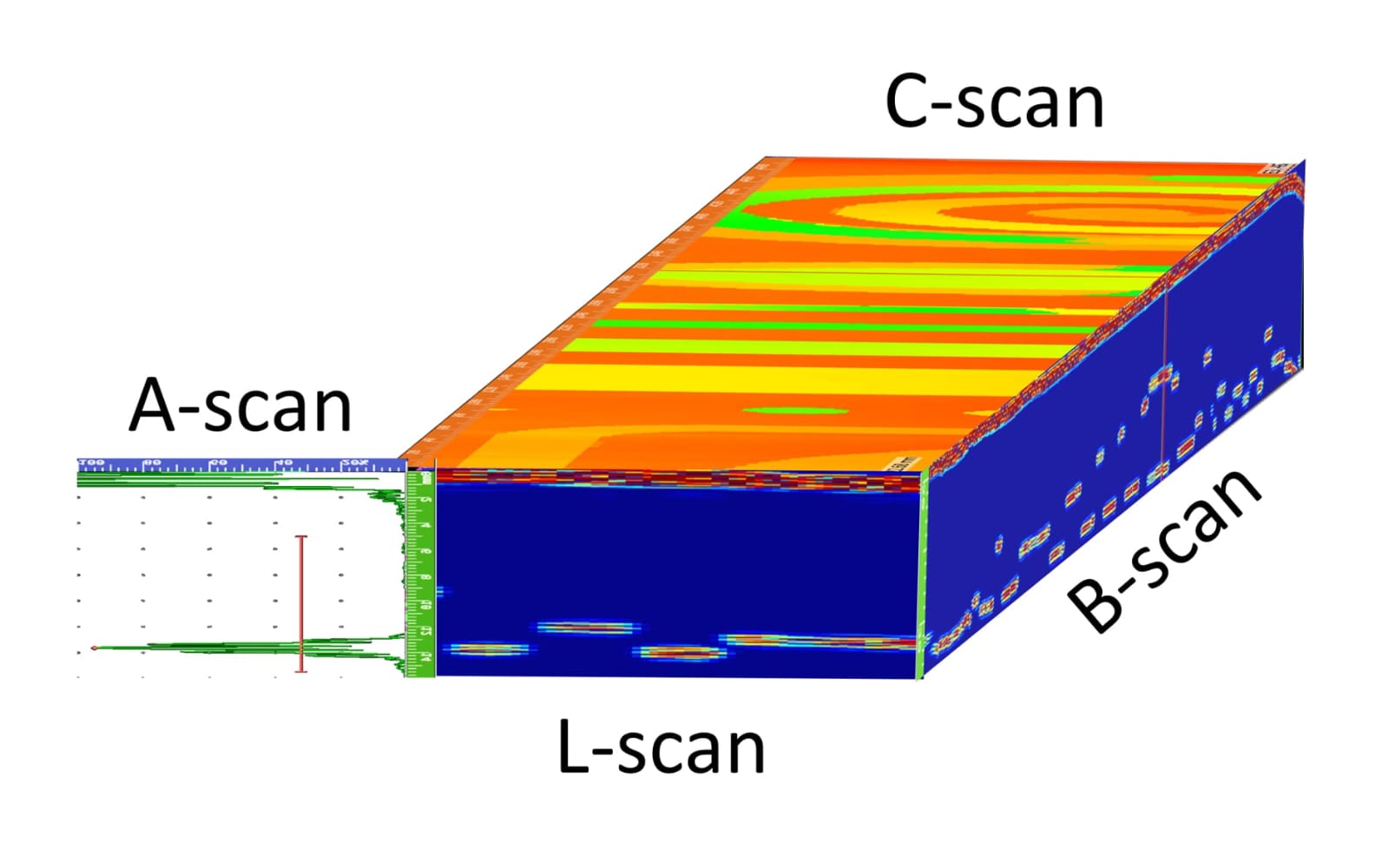

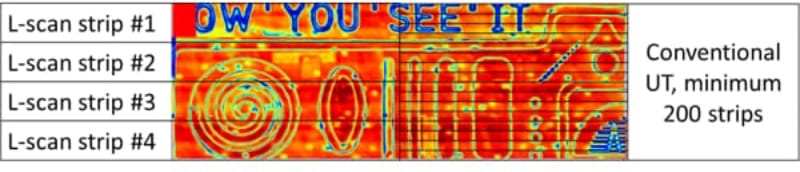

Once the transducer moves, it uses an encoder to record a high-resolution mapping of data using A-scan. To perform a mapping over a large surface, multiple strips can be recorded one after the other to cover all the surface.

This type of scan is a waveform representing the amplitude of the ultrasound signal as a function of time or distance of propagation. Another view can be generated from this record, the C-scan, which is essentially a view generated from a 0-degree linear scan. It can be described as a two-dimensional graphical representation displaying the gate information obtained relating to signal features in a top plan view of the test structure. A C-scan uses a data gate to extract information from A-scan data.

Benefits of the linear scan

One of the main benefits of linear scanning is the high-resolution inspection results. Indeed, each element represents a probe in itself. Thus, compared to a single-element transducer, it is possible, in a single pass, to have a high-class quality image thanks to the many beams that constitute the linear array.

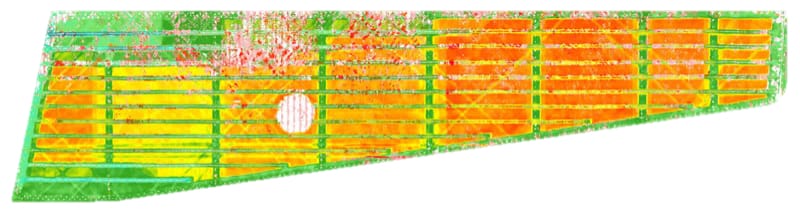

With a straight beam linear scanning, the acquisition is then facilitated and large surfaces can be inspected. The image below represents a complete large and complete C-scan mapping of a 7m long aircraft rear stabiliser performed using Sonatest RapidScan instrument.

When compared to the more complex ultrasonic Phased Array technique, it is important to mention that the technician does not have to consider any beam steering concepts with the Linear Array method because all beams are similar and normal to the surface. This greatly simplifies the application, the calibration process and eases the post-acquisition analysis for reporting.

In short, linear scanning is an appropriate solution for both composite inspection and corrosion mapping because it simplifies operator jobs and offers high-resolution volumetric inspection results.

Useful references:

- Learn more on how to analyse ultrasonic NDT C-Scan mapping

- Learn more about an optimised linear scanning workflow

- Learn more about RSflite and UTmap composite solution

- Learn more about the WheelProbe2 scanning solution

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags