Lack of fusion (LOF) defects occur when the weld metal does not fuse properly to the parent metal leaving an area within the weld with a very thin gap. This reduces the strength of the weld and can cause failures in the service of the weld.

There are many types of LOF defects; these include LOF in the root, side wall and toe areas of the weld. It can also happen between weld runs within the body of the weld, this is known as ‘lack of inter run fusion’.

This blog covers the use of ultrasonic inspection techniques for detecting LOF defects. We examine one of the most common types, which is the lack of side wall fusion. It also highlights how Sonatest’s advanced equipment is currently being utilized in the field, showcasing our unique capabilities in improving the detection and sizing of these defects.

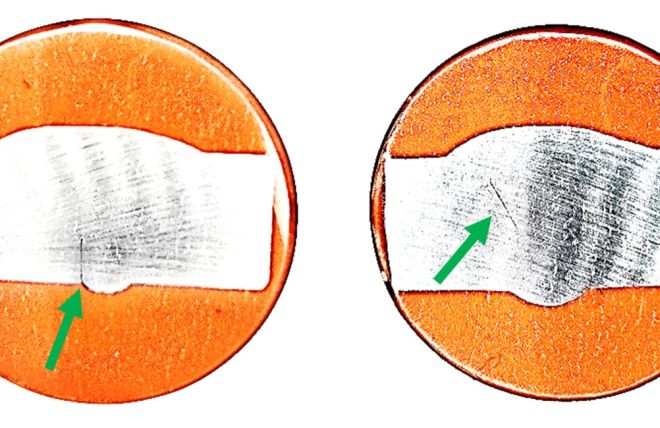

Fig. 1 – Lack of root fusion (Left) and lack of side wall fusion (Right). Images of weld macros, supplied by Sonaspection

Ultrasonic Methods

In this blog, we have utilised the WAVE and VEO3 ultrasonic systems to scan and detect an example of a lack of side wall fusion; this shows the advantages of each method in the detection and sizing of this type of defect. The methods used are as follows:

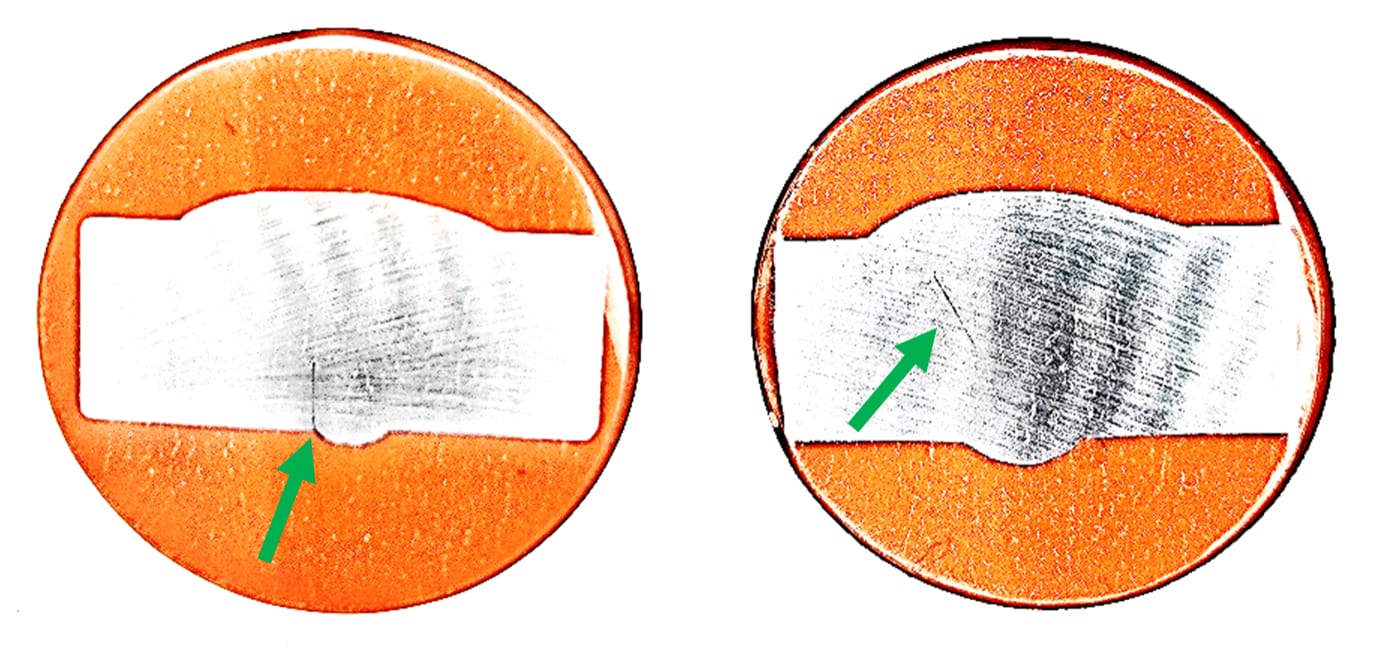

- Conventional UT – Standard single element angled inspection; the most commonly accepted form of UT weld inspection used worldwide.

- Phased Array (PA) – PA inspection is an advanced ultrasonic technique that uses multiple element transducers to create ultrasonic beam sets at a given angle and focal point within the material.

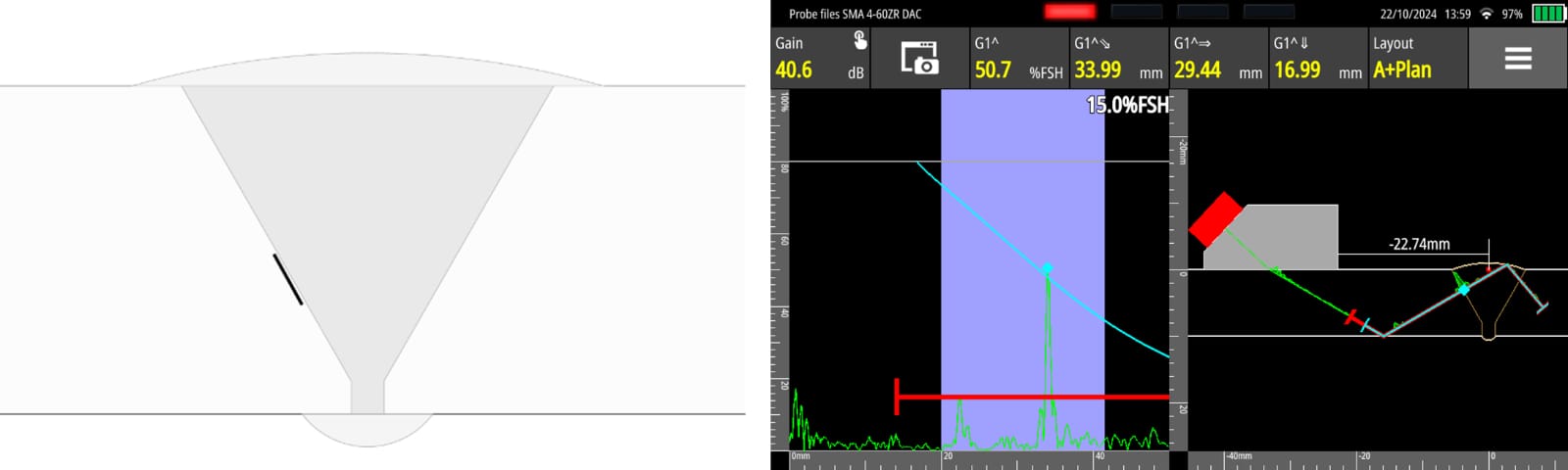

- Time of Flight Diffraction (TOFD) – TOFD is a dual probe technique that detects and sizes flaws by measuring the time of flight for diffracted sound waves from the tips of flaws to travel through the material.

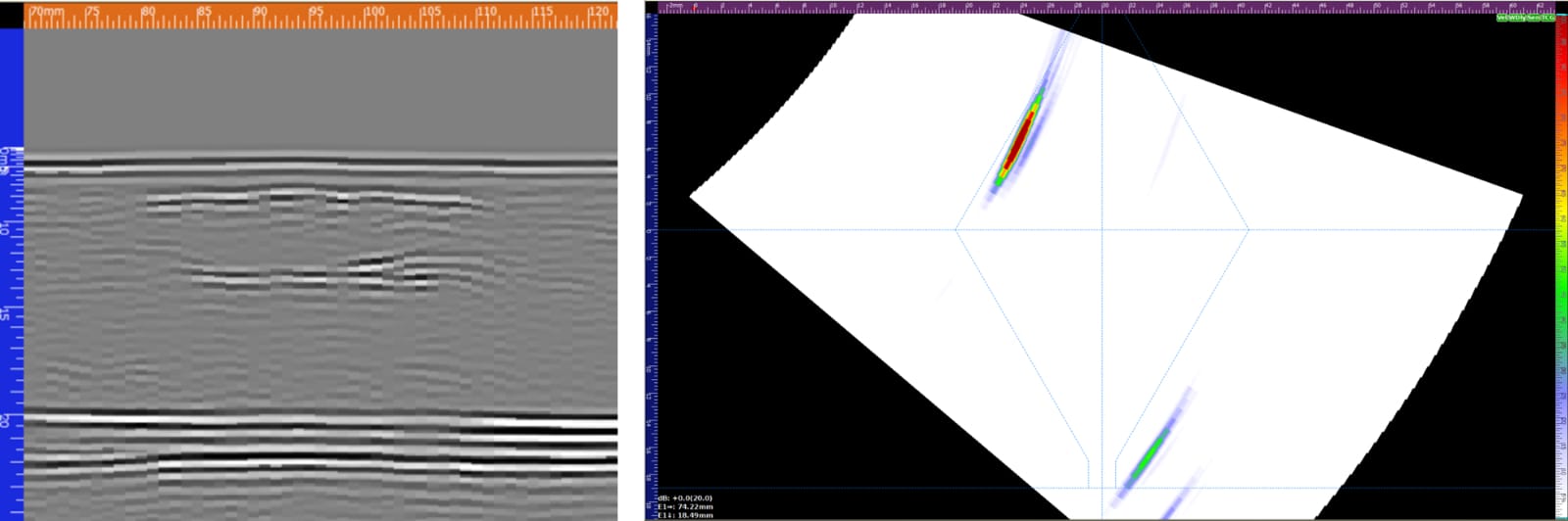

- Total Focusing Method (TFM) – TFM is an advanced ultrasonic imaging technique that uses FMC data to capture high-resolution images that are focused on every point of a region of interest.

- TFMi – TFMi is a unique technique developed in partnership with Holloway NDT, that unites up to 4 TFM propagation modes into a single image. This produces high-fidelity images of defects' shapes that other methods cannot define.

For more information on weld inspection using the above techniques see our library of application and solution notes.

Lack of Side Wall Fusion

Lack of side wall fusion (LOSWF) defects occur on the prep face of a weld between the parent material and the weld material and are generally wholly entrapped within the final weld. They can occur due to many factors, including too high a welding speed, incorrect weld settings, and poor preheat of the parent material.

LOSWF defects present a flat face due to the original prep of the weld. On a known angle, it can easily be detected by the inspector where the angle is on a V weld as ultrasonic inspections can be set to hit this surface at 90° to maximise the return signal. However, in U and J prep welds, this angle can be very difficult to hit at 90°, so the operator may have to rely on tandem techniques or TOFD where the defect's orientation does not impact detectability.

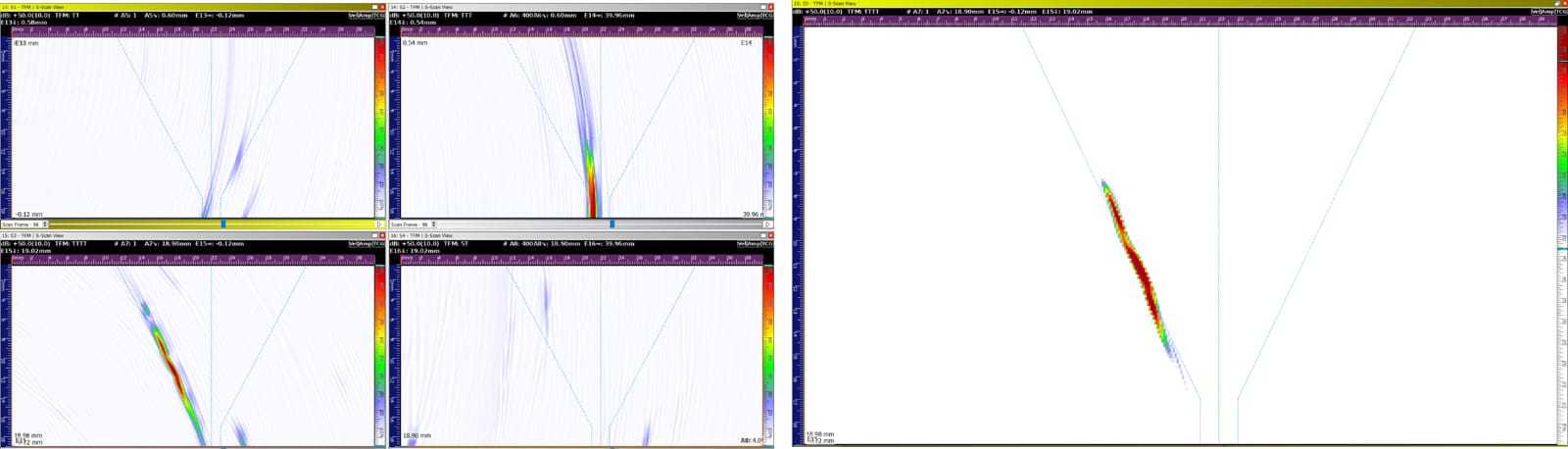

As can be seen in the scan images below, the LOSFW defect was easily detected in all ultrasonic methods. In this case, TFMi did not improve upon the TFM TTTT mode result. In Figure 4 (right image), we enhanced the image using colour pallet manipulation.

Fig. 2 – LOSWF weld profile (Left) Conventional UT detection on the Sonatest Wave (Right)

Fig. 3 – LOSWF detection as seen using TOFD (Left) and PA (Right) on the VEO3

Fig. 4 – LOSWF on TFM (Left) TFM TTTT enhanced image (Right)

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags