- Application Notes

Wave Nozzle Inspection

The inspection of nozzles and nodes requires a high level of skill and experience for both inspection and interpretation. Under normal circumstances a technician would have to manually draw out the weld profile to aid in positioning and interpreting indication signals. With some nozzles and node configurations this could require 3 to 5+ diagrams to cover the different profiles around the weld.

With the Wave 1.8 CAD import feature, all of the profiles can be viewed on a single scan plan screen, and utilising the live ray tracing for the probe being used the technician is able to accurately position any signal received and interpret that signal with confidence.

Inspection

The test shown in the data were carried out on a set through nozzle sample with induced defects. The nozzle was 12mm thick x 200mm diameter set at 90° through a 25mm thick curved plate with a single bevel weld.

The probes used in this inspection were 4MHz, 0° 45°, 60° and 70° Sonatest Starc shear wave transducers. The transducers were positioned on both the main pipe and the nozzle itself to achieve full coverage of the weld.

Fig. 1 - Nozzle sample inspected

With a CAD DXF file created on Beamtool we had the profiles for 0°/180°, 90°/270° and 45°/135°/225°/315°, once the scanning surface, reflective and non-reflective surfaces were assigned this was imported to the WAVE for the inspection.

Fig. 2 - Assigning the surface properties

Inspection Results

All 4 defects were identified and correctly positioned using the interactive scan plan. The live ray tracing and ability to quickly switch between each profile made the process of evaluation and interpretation easier and much quicker than the manual positioning using diagrams and beam spreads.

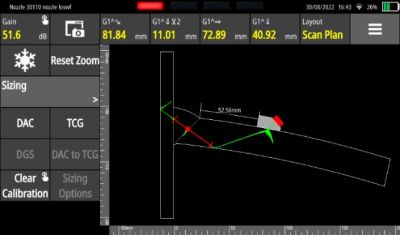

Fig. 3 - Lack of Root Penetration indication

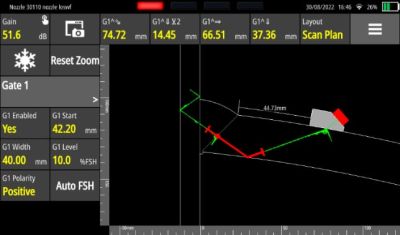

Fig. 4 - Lack of Side Wall Fusion indication

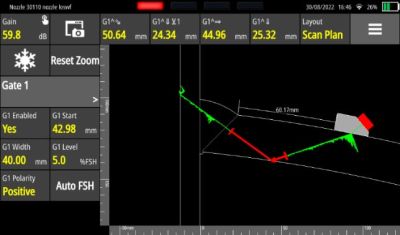

Fig. 5 - Side Wall Crack

Fig. 6 - Grouped Porosity

Conclusion

Benefits of using the WAVE 1.8 CAD import feature:

The Wave replaces the need for a set of manually created drawings for an inspection, it also concentrates everything needed into the screen being used for inspection, this removes the need to go between flaw detector and paper to locate indication signals.

A digitally created scan plan can be created before the site visit or on the day, providing a more detailed representation of the item under inspection with the ability to include multiple profiles in the same scan plan. This can reduce time spent on site and inaccuracies associated with creating diagrams manually on paper.

Live ray tracing provides an accurate representation of the ultrasonic beam and takes into account curved surfaces or complex geometries which can be difficult to replicate with paper diagrams and beam spreads.

While the inspection is underway, screenshots can be easily taken by one touch, making reporting much easier. These images can be quickly downloaded using Sonatest “companion” software and then placed into reports so that the customer has a clear visual identification of where a defect is positioned within the weld.

The Sonatest WAVE gives greater confidence for inspectors and clients by giving clear and precise images of where a defect is located or even identifying if a reflection is from a defect, geometry or mode conversion.

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | WAVE digital flaw detector | |

| Probe | Suitable shear wave and transverse wave transducers | |

| Calibration Block | WAVE Companion Software |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products