- Application Notes

Low Frequency PAUT Inspection of GFRP

In this application note we will be focussing on the inspection of glass fibre reinforced plastics (GFRP), specifically those used in the manufacturing of wind turbine blades, but the principles used are applicable across the range of GFRP parts. Common defects in this material will include air voids/bubbles trapped in the epoxy (porosity), delamination’s between fibre layers especially around areas with thickness changes and damage to the spar due to excess stress on the blades.

Fig. 1 - VEO3 GFRP scan setup

Inspection Procedure

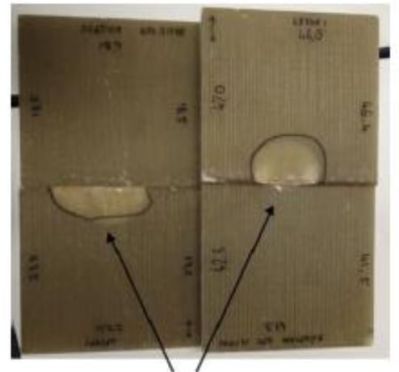

The test procedure was demonstrated on two samples as shown below, the parts being inspected are sections from a wind turbine blade, both sections have 2 different thicknesses, The defects start in the area where the thickness changes and continues part way into the thicker side of the samples.

Fig. 2 - Two samples inspected for this trial with areas of simulated defects. Simulated lamination (left plate) and simulated area of thickness loss (right plate)

Practical Outlines

Need for Phased Array Inspection

- The need for inspection of wind turbine blades begins at their manufacture and continues throughout their lifespan as each blade comes under different stresses from their environment.

- During the manufacturing process, delamination can occur, these defects are often hidden from the visual view and need to be ultrasonically inspected. Common areas for delamination are around drilled holes (for fasteners) and around edges/thickness changes.

- Another defect that can be introduced during manufacturing is porosity, this is an area or air/air

- Bubbles that get trapped during the resin injection and curing process.

- Over the working life of a wind turbine blade inspections need to be made to help discover new defects that may be formed, these can include:

- Separation from the spar due to high stress

- Impact damage from birds

- Delamination caused by too much flex of the blades while in operation during high winds

Benefits of Inspection

- Wind turbine blades are high value items, they are also hard to transport and change. Therefore, it’s very important that proper inspections are made, reducing the need to change blades unnecessarily, as well as avoiding in service failures.

- Using this test method, the inspection can be performed while the blades are attached to the turbine via rope access, meaning there is no need to remove the blades and bring them to a ground location, reducing cost and overall down time.

- Not all delamination will be failures, using phased array, it makes it easy to monitor any growth in delamination size, therefore finding the right time to remove or repair the turbine blade.

- Delamination, wrinkles, porosity sizing and characterisation is improved with UTstudio+ and could even be sized automatically with the unique UTmap annotation.

Conclusion

- The Sonatest low frequency phased array transducer, paired with one of our fast, capable units gives an easy to use and reliable way to guarantee thorough NDT inspection of wind turbine blades.

- Due to the versatility of our units, many other inspections related to wind turbines can be achieve, for instance the welds in the supports as well as checking for corrosion in specific areas.

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | VEO3 / RSFlite / PRISMA Phased array data acquisition units | |

| Probe | X6B range of low frequency probes, available in 0.5MHZ and 1.0MHz versions | |

| Encoder | AXYS Encoder |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products