- Solutions

Long Seam Weld Inspection - Manual and Encoded

Long seam welds can be found in pipelines and other structures such as fume towers, storage vessels etc. Inspection of these welds can be difficult as the curved OD and ID surfaces reflect ultrasonic beams differently depending on the angle of incidence, if this is not accounted for, the results can be positioned incorrectly in the weld and out of sensitivity due to the spreading effect of the curved surface reflections.

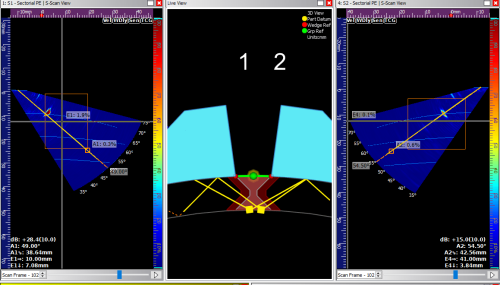

The VEO3 uses specialised “Curved surface correction” software to ensure there is adequate sensitivity at the region of interest and that the resulting indications are plotted correctly on the S-Scan.

Fig. 1 - long seam weld semi automated scan setup

Fig. 2 - Curved surface S-Scan and 3D corrected view

Single Sided Manual Inspection

Manual inspection of seam welds can be carried out with a single probe setup , either timed scanning or with an encoder.

For a comprehensive package for carrying out manual PA inspection see Package 1 at the end of this document.

Single / Duel sided Semi Automated Inspection

Semi automated scanning can be carried out utilising scanners to position and guide the PA transducers for the full weld inspection. This has the advantage of maintaining a constant probe standoff, fully encoding the scan for accurate defect measurement, and also allows for the use of multiple probe setups to be used simultaneously for quicker inspections.

For a comprehensive semi automated inspection package see Package 2 at the end of this document.

Recommended Tool Package 1 (single sided manual inspection)

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | VEO3 32:64 PA Acquisition unit with curved surface correction software | |

| Probe | D1A series probes available in 2.25MHz, 5MHz and 7.5MHz variants. | |

| Wedges | D1BW Series | Wedge choices with contouring compatible with the test surface curvature |

| Cable | D1-CABLE-001 | D1-CABLE-S-QX2 - 2 meters |

| Adapter | ADAP-006 | 64:64 IPEX Splitter |

| Encoder | AXYS Encoder |

Recommended Tool Package 2 (semi-automated DLA inspection)

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | VEO3 32:64 PA Acquisition unit with curved surface correction software | |

| Probe | D1B Series (x2) Available in 2.25MHz, 5MHz and 7.5MHz versions | |

| Wedges | D1BW series (x2) | Wedge choices with contouring compatible with the test surface curvature |

| Cable | D1-CABLE-003 | D1-CABLE-D-QX2 (Dual cable) – 2 meters |

| Adapter | ADAP-006 | 64:64 IPEX Splitter |

| Scanner | JX-1001 OR PX-MULTIMAG-2-VEO | Jireh; 2 Probe PA/TOFD Scanner OR Phoenix; VEO Multi Mag 2 (PA/TOFD) Scanner (including tubes and fitting) |

| Irrigation Kit | JX-1003 and JXCMA014 OR 196102 | Jireh; Irrigation kit and 7.9 litre (2.1 US gallon) portable manual couplant pump OR Phoenix; 7Lt Portable Hand Spray Kit |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products