- Application Notes

Improved Bolt Inspection with Combined Ultrasonic Techniques

Bolts are used as fasteners in many industries and for different equipment, such as cranes and steel structures. They play an important role for structures by ensuring a proper fixation between parts.

When ultrasound inspections take place, inspectors can detect major defects located along of the centre of the bolts. Defects under the thread are very difficult to detect by conventional ultrasound because, in most of cases, echoes from the thread overlap those from the defects.

With the help of phased-array associated with TFM, inspectors will be able to cover a larger area (bolt body and region under the threads) with just a single ultrasound shot. In this case, the probability of detection can be considerably increased and the time to perform the inspection is sensibly significantly reduced.

Fig. 1 - Test bolts used for this inspection

Images

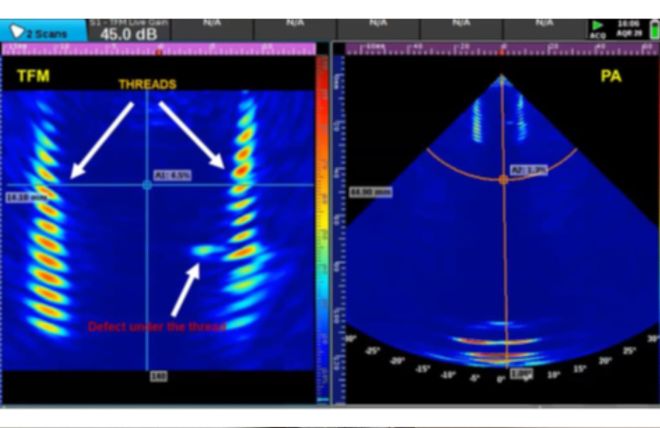

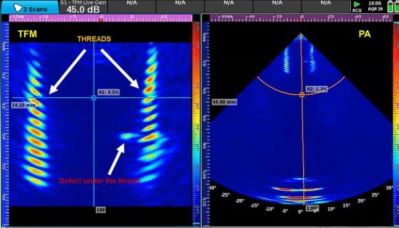

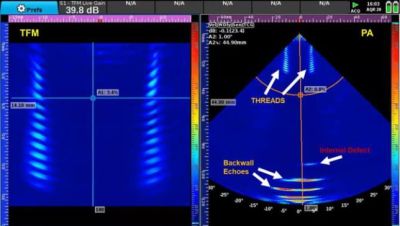

The left side view of Fig. 2 below represents a TFM scan of the bolt’s threaded section. The TFM scan ensures a superior level of resolution and improves defect detection and characterisation. The crack defect under the thread is highly distinguishable among the echoes from the threads. Such a level of resolution is a game changer when it comes to reject a defect.

The right side view of Fig. 3 below represents a phased-array scan of a crack – a flaw inside the part volume. The phased-array scan not only covers a larger volume more quickly, but it also is a technique known for having more energy and sound penetration compared to TFM. This increases the likelihood of detecting a deep flaw.

Fig. 2 - TFM scan of the bolt’s threaded section

Fig. 3 - PA scan of a crack

Practical Outlines

By scanning your part with a multi-technique combination, you can combine the advantages of both techniques in one single session of data acquisition. In a similar manner as the phased-array and TOFD combination, TFM could be used to focus on the thread of the bolt to maximise the POD and flaw characterisation of this area. Phased-array could be used to cover the rest of the part volume for which the resolution is not as important. This feature saves time. Furthermore, it ensures identical coupling conditions and positioning for easier comparisons between techniques. By combining both techniques, you would achieve the following benefits:

Benefits of the TFM approach

- High resolution and image quality enhancement

- Better sizing of defects located on threads

- Improved probability of the detection of defects

Benefits of the Phased-Array approach

- Improved sound penetration for larger bolts

- Increased volumetric coverage

- Increased acquisition speed

Recommended Tool Package

| Category | Part# | Description |

|---|---|---|

| Acquisition Unit | VEO3 32:128 | |

| Probe | X2B-5M32E with a side entry cable | |

| Scanner | Creo Bolt Scanner with large probe cradle setup and offset probe holding plate |

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products