- Application Notes

Friction Weld Inspection

Friction welding is a solid-state welding process that generates heat through mechanical friction between two work-pieces in relative motion to one another with the addition of a lateral force called “upset” to plastically displace and fuse the materials. This process is commonly used on cylindrical metal or thermoplastic components in aviation and automotive applications.

Fig. 1 - Friction welding of bar components

Inspection Methods

There are three potential inspection methods:

- Conventional UT single compression probe - This is the simplest method but requires the component to have access to a surface that allows ultrasonic interrogation of the weld, e.g. the end of a solid bar or plate. This method is a proven technique for detecting areas of lack of fusion but relies on the geometry of the part to favour the technique.

- UT Tandem Pitch & Catch - Two conventional angled probes are used, both on the same side of the weld, the method is used to detect defects at a vertical orientation to the part, not normally detected with angle probes. This method can be difficult to setup and for larger parts may require multiple passes to achieve full coverage.

- Time of Flight Diffraction (TOFD) - Utilising two transducers, one on either side of the weld, the full weld volume can be inspected in a single pass. TOFD can also detect defects in any orientation.

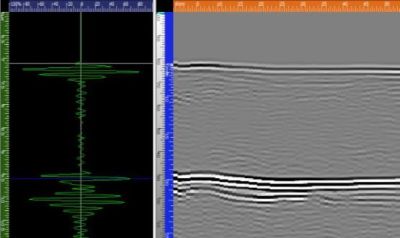

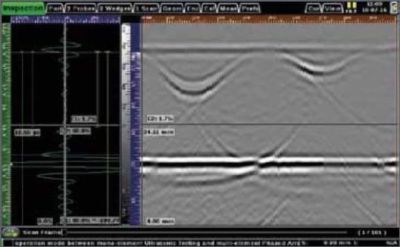

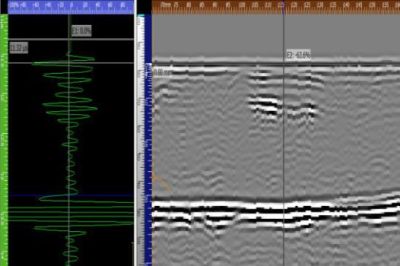

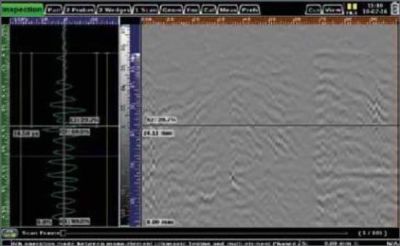

The following images show examples of typical signal responses.

Fig. 2 - No defects

Fig. 3 - Side drilled hole in bar

Fig. 4 - Lack of fusion defect in plate

Fig. 5 - No fusion

Conclusion

Although all three methods can be utilised for such applications, the conventional UT pulse echo and the TOFD approach is favoured compared to the tandem pitch & catch method, due to the display advantages, the pace in data interpretation and improved repeatability. Inspection can be carried out using the Sonatest VEO3 or Prisma platforms and the Sonatest range of digital flaw detectors.

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education