- Educational Notes

Accurate Top Views using Extraction Boxes

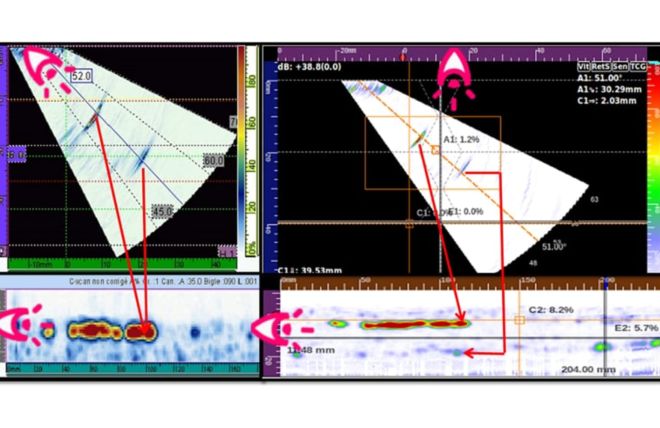

Using Sonatest’s unique extraction boxes, inspectors can directly extract the height and width of the flaw without any compromise.

Weld inspection data needs to be recorded if the full benefits of using the phased-array technique are to be obtained.

Full inspection data not only makes further analysis possible but it will also provide more clarity when identifying flaws. This advantage extends the use of phased array to allow inspectors to replace radiography under certain conditions (ASME Code, Section VIII, Division II). In this specific case, the rejection criteria of the inspection data are classified and based on a non-amplitude technique. In other words, it is no longer the echo amplitude that determines whether or not a flaw is rejected. Rather, it is the overall volumetric data (height and width). This is when an extraction box is very useful for further analysis of the inspection data.

Download File (pdf, 310.3KB)

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education