Riser pipeline evaluation is an important aspect for the offshore industry as risers provide a means of transfer of product between the pipeline on the seabed and the processing equipment on platform.

The dominant corrosion and integrity issues affecting offshore rigid and flexible pipelines and risers in the sea were examined. For many aging rigid pipelines, extension of life beyond the design criteria is increasingly common, and the dominant integrity issues are associated with internal and external corrosion. The risk assessment indicates that gas riser pipelines will have a high-risk level for the splash zone segment and a medium-risk level (2D) for the above and below water segments.

Preserving drill bits in the oil drilling industry can result in significant cost savings. A loose diamond tooth can damage other teeth and even destroy the entire head. Given the high value of this asset and the large investment required for oil drilling projects, owners always consider non-destructive evaluation methods for such projects.

In this blog, we will cover only 3 critical components that require NDT offshore care. For example, many rig parts require corrosion monitoring, but our focus will be on the riser pipelines, bolts and drill bits.

The riser platform can transport oil and gas from seabed to platform1. Those advanced pipeline contains bolts that are used to secure the riser to the platform. Offshore companies also take care of their precious drill bits. That is why the teeth are inspected so they are not destroyed before its average lifetime.

Corrosion Mapping

80 foot long riser stack

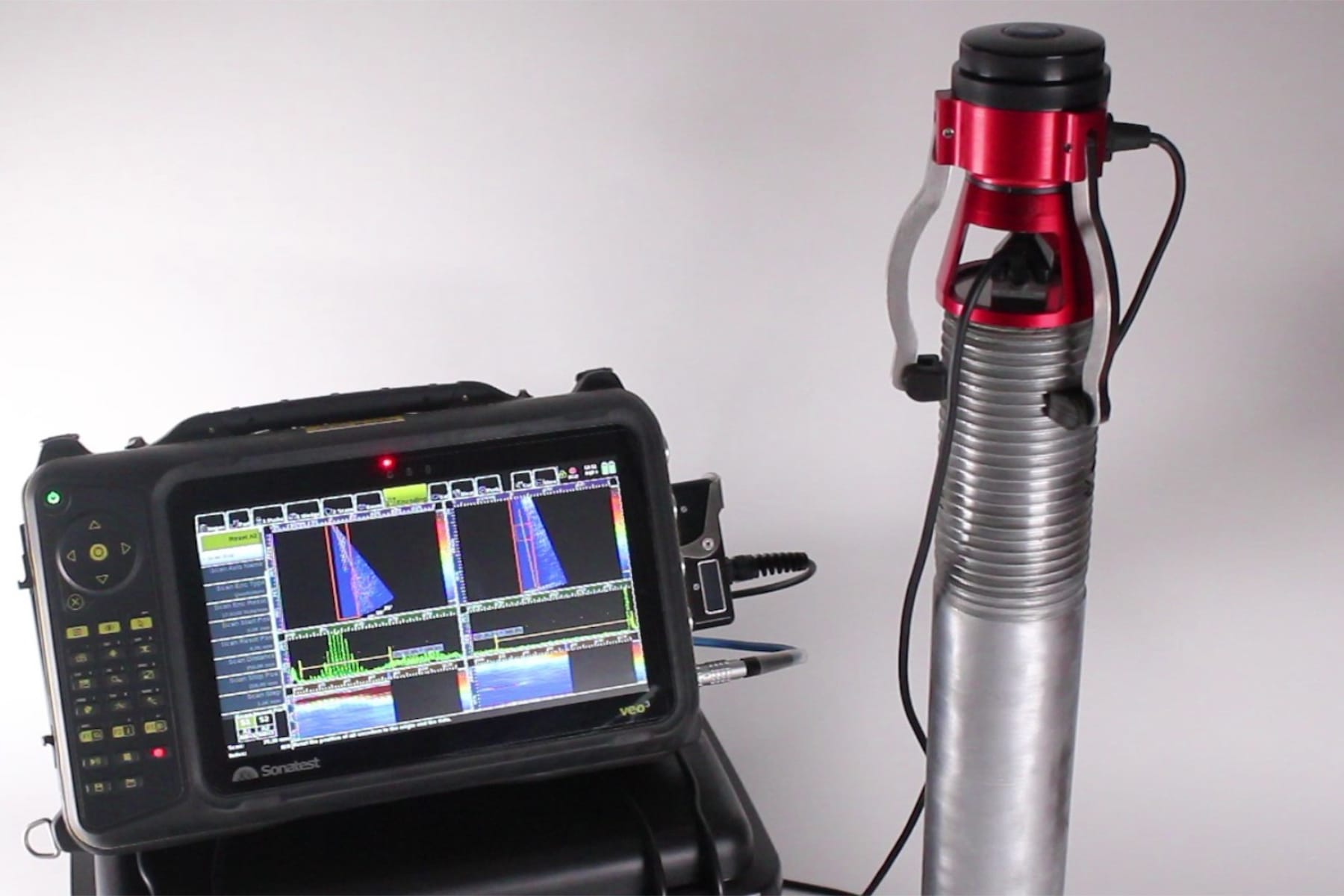

For corrosion evaluation of Riser Pipeline, Sonatest Veo3 can be used to measure thickness using C-scan mapping for its both main line and auxiliary lines. The C-scan mapping is a technique that uses phased array technology to create a 2D image of the internal structure of a component. By using this technique, Sonatest Veo3 can provide detailed images of the thickness of the pipeline which can help identify any areas that may be corroded. However, there are some challenges when using C-scan mapping for corrosion evaluation such as scale and mud. The design of the veo3 allows smart integration of probes, scanners, and software analysis tools.

Riser Bolts

For Riser Bolts inspection, Sonatests Veo3 can use the Creo Bolt Scanner which has a modular design and an internally built encoder that makes it suitable for extensive in-field operation. Cam-linked adjustable legs ensure a fast and repeatable ultrasound results over each bolt. Our hard-faced PA probe models are also a good option for long life against rough surface like this one.

Bolt scan setup using a veo3

Drill Bit Teeth

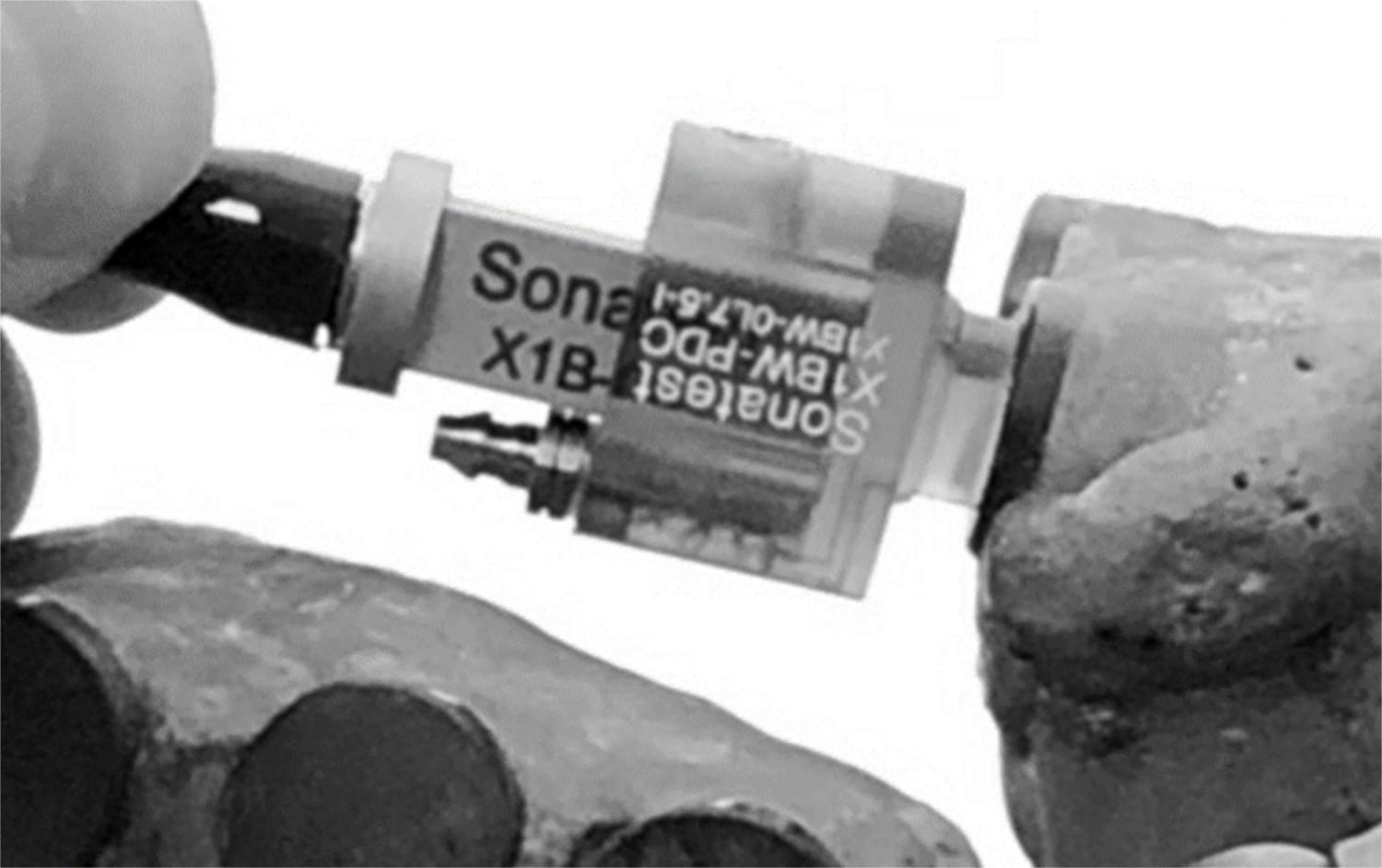

For drill bits inspection, Sonatest Veo3 can use the Sonatest X1B probe which is designed to inspect for defects such as lack of bonding and wear. The Sonatest X1B probe is designed to fit into tight spaces and can provide detailed images of the internal structure of the drill bit which can help identify any defects that may be present.

Sonatest X1B probing one tooth

The Sonatest Veo3 is an advanced flaw detector that uses phased array technology to inspect materials for defects. When it comes to combining multiple inspections in the offshore and drilling fields, it can solve dozens of critical NDT inspections.

[1] What is a Pipeline riser, WeBBusterZ Engineering, February 21, 2023

https://www.webbusterz.org/what-is-a-pipeline-riser/

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags