This second part explains the consequences of false calls in ultrasound inspection activities. There are recurring and challenging situations where UT is prone to errors and misinterpretation.

False Call Reality Check

There are key studies that shed light on the realities of manual NDT inspections. The European Commission (in 1999) and Health and Safety Executive (in 2008) in the UK conducted a compilation of the false calls (both false negative and positive) and revealed a 3% linear rate of unnecessary repairs.

In the field of ultrasound testing challenges, the NDT industry often contends that the intricacies of inspecting complex weld geometries make false results somewhat justifiable, a notion accepted by the public mindset.

Identifying Challenges

Initially, the risk of errors is extensive, stemming from various sources, such as ultrasound parameters, incorrect calibration, sensitivity levels, and more. Secondly, the UT method doesn't yield an image result like an RT shot or a simple photograph. It demands skill and a high level of interpretation. The A-scan peaks and thickness locations don't offer an accurate representation of an indication's shape. It's analogous to using a very narrow-beam torch in a dark room to search for elusive objects, limited information and potential unreliability due to natural corners and reflectors throughout the room.

Financial Implications

For each false call in a daily structural weld inspection, the estimated cost of the average consequence is $75 USD, equivalent to approximately one hour of disruptions for managers or welders to address a repair task. With three (3) unnecessary repairs per day, the Wave recoups its cost 1.5 times over just one year of operation. The return on investment (ROI) after 8 years demonstrates a ratio of 12 to 1, signifying a substantial improvement and a clear advantage for investors, alleviating the burden on quality budget expenses.

In exceptional cases, where repairs are more extensive or pose a high-risk threat, inspectors face the pressure of initiating a massive repair process, potentially involving the replacement of a significant pressure vessel asset. These types of situations may even lead to an unexpected production stop, representing the ultimate undesirable expense for a facility.

Comprehensive A-scan Interpretation on Complex Parts

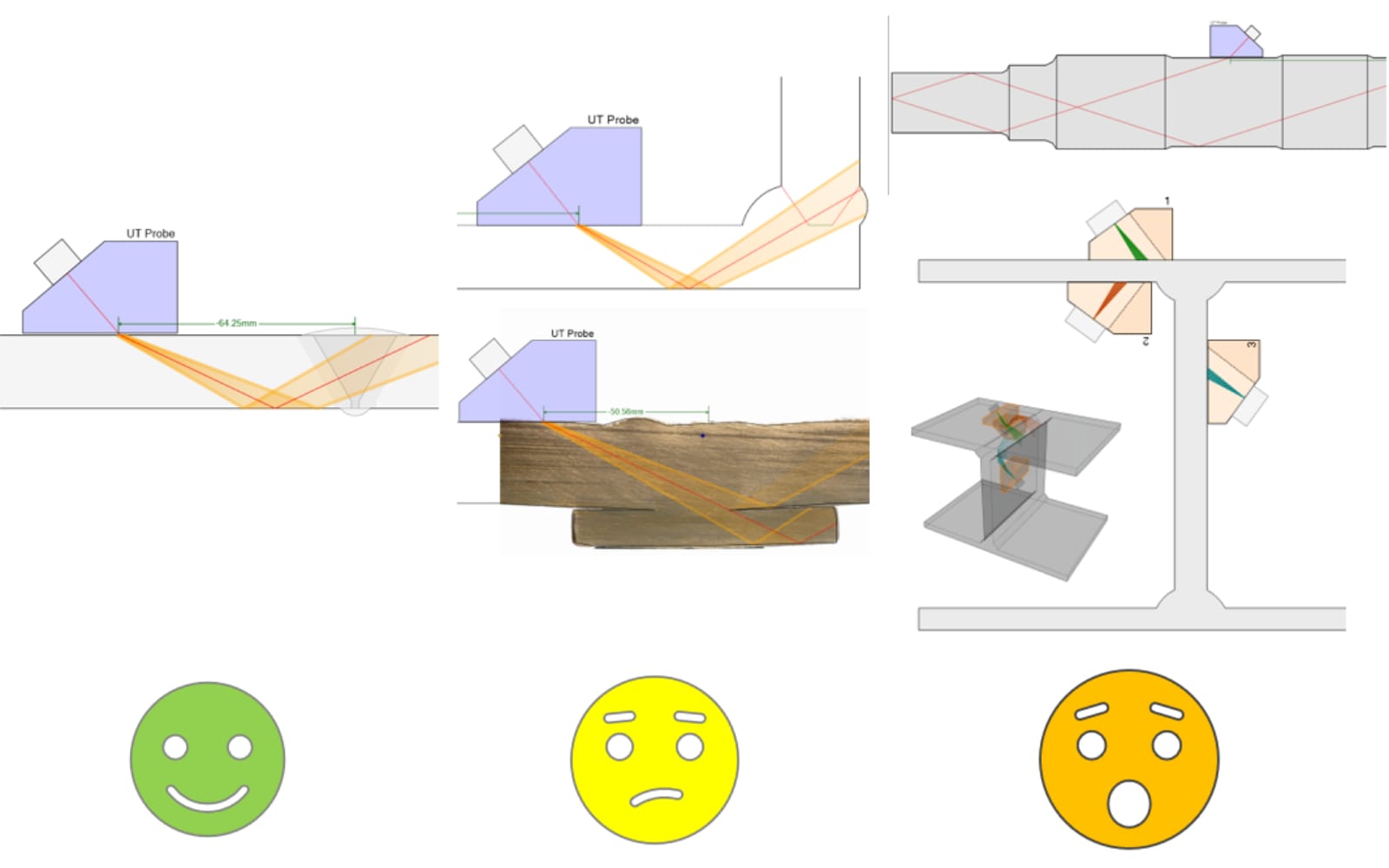

In practical scenarios involving tricky inspections, meticulous attention is given to procedures to prevent misinterpretations. Typically, these procedures precisely outline the probe placement and pinpoint the region of interest where the flaw is anticipated. Occasionally, they may emphasize natural geometric echoes, which might be characterized as defects.

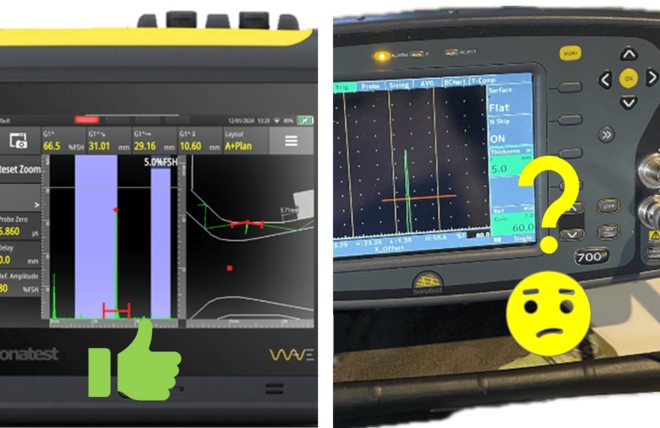

The Wave offers a distinctive advantage with its fully customizable scan plan and seamless live interactivity with both the probe and the A-scan rendering .

Intuitive Part Editor

Viewing our Comprehensive Scan Plan

This way, you can think of a complex geometry, import its challenging design profile and use the interactive ultrasound reflections to understand how the beam acts in the part. When you don’t have the drawing, you can import the image in BeamTool and draw the geometry lines so it can be exported in a DXF file.

Story of a complex inspection now made easy.

Bonus: Fast Training Progression

The interactive scan plan is an enhanced learning feature for early adopters. Its full inspection immersive testing helps young inspectors gain more experience. Did you know that our scan plan can also work in conjunction with the A-scan?

Empower the Ultrasound Testing Once Again

The Sonatest Wave offers an unparalleled user experience in flaw detectors, providing a superior evaluation tool for challenging conditions and complex geometries. The instrument's capabilities empower every technician, elevating them to a superior professional. Sonatest continues to enhance the quality of ultrasound, reaffirming its commitment to excellence.

Please contact our Applications Team if you have any questions. You can also find more solutions on our website.

Stay up to date with our latest content. Sign up here to get our blogs delivered straight to your inbox.

News Filter...

The latest news from Sonatest direct to your inbox.

Tags

Related Products