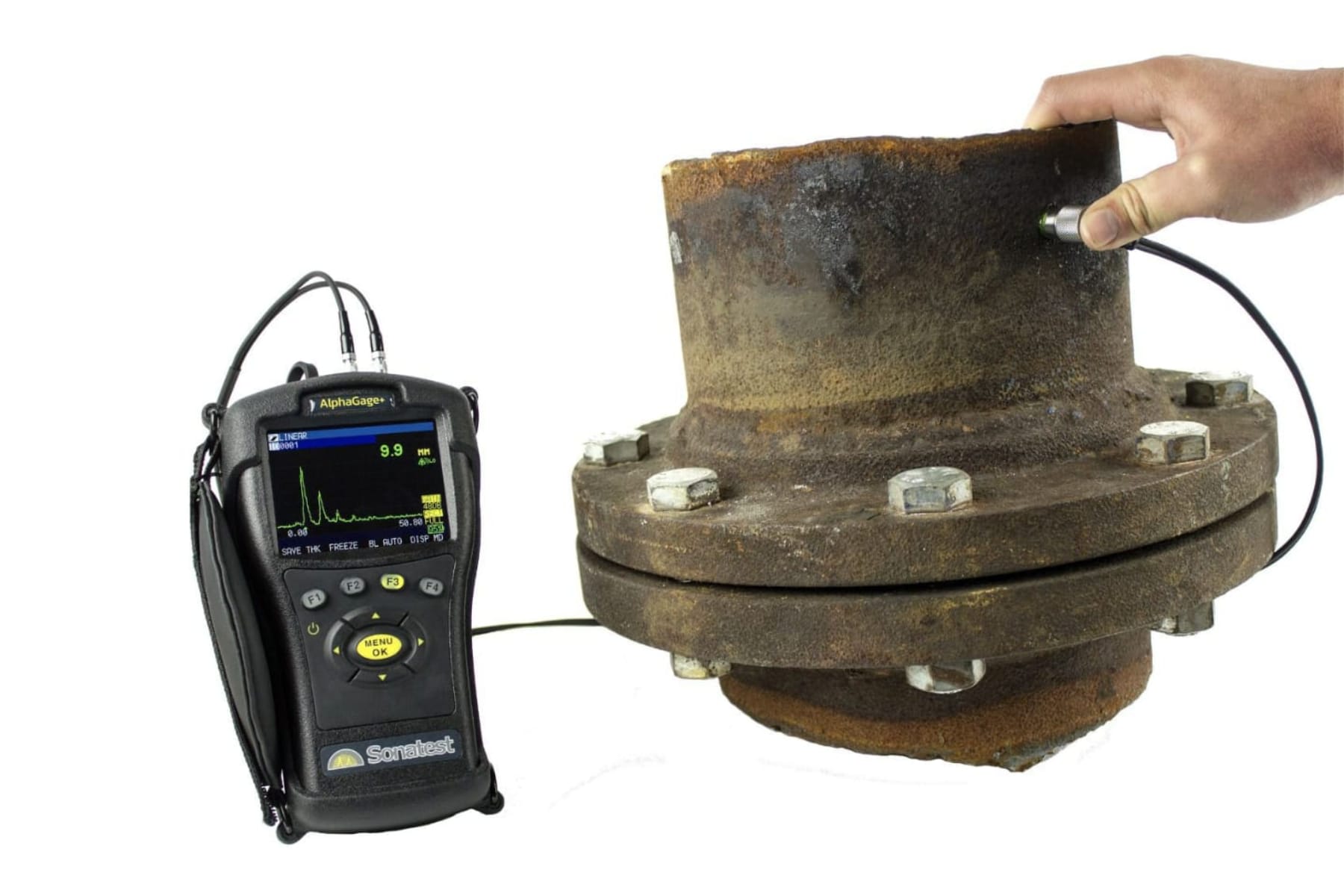

Alphagage+

As a leading solution for corrosion assessments and precise thickness measurements, the Sonatest AlphaGage+ instrument employs advanced technologies tailored to different industry needs.

Overview

AlphaGage+ Corrosion (C )

Uses dual element transducers to measure remaining wall thickness on primarily steel structures subject to corrosion.

- Compatible with a wide variety of dual element and a limited number of single element transducers

- Wide thickness range (.020” to 23” depending on gage type, material and transducer)

- Echo-to-echo readings to ignore coatings

- High temperature probes available up to 950F/509C (intermittent use)

- Temperature correction

- Gridview

- Password lock

- Supervisor and other locks

- 2,700 stored setups

- Change color and vibrate on alarm

AlphaGage+ Precision (P)

Allows for the use of single element transducers along with up to 2,700 stored application setups with 1 micron resolution.

- 0.006-23” range in steel

- 1 micron resolution (0.0001” or 0.001 mm)

- Single element, contact, delay line and immersion transducers (1-30 MHz)

- Supervisor and other locks

- 30 Mhz bandwidth

- Zoom Auto Tracking

- Multiple modes for challenging applications

- Square wave Pulser

- Auto Phase Reversal Detection with alarm

Features

Standard Features

- Echo-to-Echo “Through Coatings” functionality (Corrosion Models Only)

- Up to 27 Hour battery life (high-capacity re-chargeable battery pack via the USB port)

- Change color and vibrate on alarm (ideal for inspections in loud environments)

- Wide thickness range

- Inches, mm or μSec

- Velocity mode

- Fast Min/Max mode to display actual thickness and minimum and maximum at the same time

- Multiple languages

- Available Live Waveform with gain, range, rectification, blank adjustments (with W Upgrade only)

- 2 GB micro SD card standard, expandable to 32 GB

- Available Datalogger interfaces with Microsoft Excel (With DL Upgrade only)

- Designed for IP67

- Simple one hand operation

- Field upgradeable software options

Available Packages

- Alphagage+ C: Corrosion Features Only

- Alphagage+ CW: Corrosion Features + Waveform

- Alphagage+ CDL: Corrosion Features + Data Logger

- Alphagage+ CDLW: Corrosion Features + Data Logger + Waveform

- Alphagage+ P: Precision Features Only

- Alphagage+ PW: Precision Features + Waveform

- Alphagage+ PDL: Precision Features + Data Logger

- Alphagage+ PDLW: Precision Features + Data Logger + Waveform

- Alphagage+ PDLWOS: Precision Features + Data Logger + Waveform + Oxide Scale

- Alphagage+ CP: Corrosion and Precision Features Only

- Alphagage+ CPW: Corrosion and Precision Features + Waveform

- Alphagage+ CPDL: Corrosion and Precision Features + Data Logger

- Alphagage+ CPDLW: Corrosion and Precision Features + Data Logger + Waveform

- Alphagage+ CPDLWOS: Corrosion and Precision Features + Data Logger + Waveform + Oxide Scale

C, P, W or DL Features can be added to any Alphagage+ via field upgrade!

Data Logger (DL) Upgrade

Datalogger software with B-Scan. Internally store millions of thickness readings with ID location and send readings to Microsoft Excel via Data XL interface program. File compare features shows old readings along with new readings for real-time corrosion monitoring.

Waveform (W) Upgrade

Live Waveform A-Scan. Displays the live A-scan for echo verification and real time control of range, gain, rectification and blanks. Coating thickness and substrate thickness displayed simultaneously.

Oxide Scale (OS) Upgrade

Oxide Scale (Boiler Tube). Simultaneously displays the wall thickness of the boiler tube thickness as well as the internal oxide scale at their independent velocities. Only available on PW options.

Specification

| Measurement Rate | 4Hz or 25Hz |

| Bandwidth | 0.5 MHz to 30 MHz (-3dB) |

| Connector Type | Lemo 00 (x2) |

| Size | 7.25" x 4.00" x 2.00" |

| Weight | 1.2LB w/ Li-ion Battery |

| Display | 3.5” high resolution color TFT display, 320 x 240 pixels |

| Backlight Management | LED backlight, includes variable light intensity. |

| Operating Temperature | -4 to 122°F |

| Certifications | CE certified, RHOS complaint and designed for IP67 |

| Warranty Limited | 2 year warranty under normal use on parts and labor |

Accessories

Standard Model

| Included with the unit |

|---|

| Transducer |

| - Corrosion Gage includes a DKS537, dual element 5.0 MHz, 0.375” probe with potted 3 foot cable |

| - Precision Gage includes a 2.25 - 10 MHz single element probe with a Lemo to microdot cable |

| 2 GB micro-SD card (minimum) |

| Li-ion battery w/ battery charger |

| Transport Case |

| Manual with Data XL |

| USB cable |

| Custom Rubber Boot (DLW Models Only) |

| Calibration Certificate |

Accessories

| Product Code | Description |

|---|---|

| 149103 | Plastic Carry Case |

| 149104 | Li-ion Battery Pack |

| 149105 | Rubber Boot & Neck Strap |

| 149106 | Alkaline Battery Pack |

| 149107 | Charger with USB |

| 149108 | Magnetic Ball Head |

| 149109 | Neck Strap |

| USB-09-6 | Mini USB Cable - 6 Foot |

Downloads

Brochure & Full Specification

| Type | Title | Date | Size | |

|---|---|---|---|---|

| AlphaGage+ Brochure | 11/25 | Download | 6.31 MB |

Software Updates

| Title | Date | Version | Size | |

|---|---|---|---|---|

| AlphaGage+ Software Updates | June 2025 | 3.17 | 1.5M | Download |

| Data XLS Software | Nov 2025 | 3.29 | 2.7M | Download |