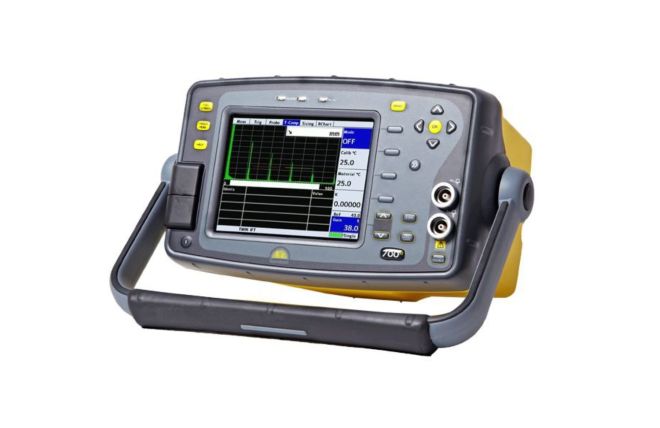

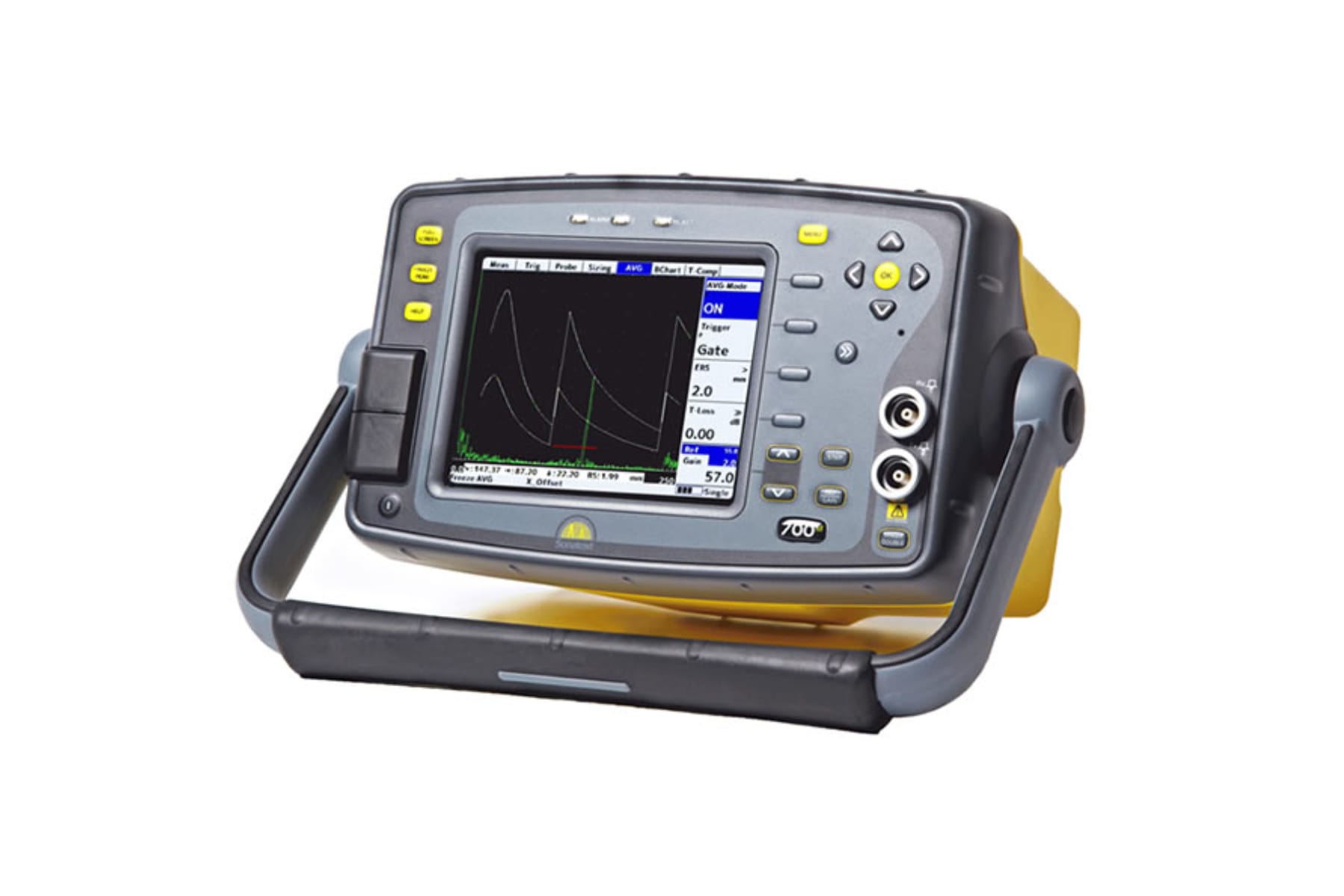

Masterscan 700m

The Masterscan name has always assured the technician of robust instrument construction combined with exceptional performance.

Overview

The Masterscan 700M offers the end user a high end narrowband flaw detector with a full VGA display, sync and proportional outputs, sync input and a Spike and Square Pulser.

Features can be added and upgrades performed in the working environment, reducing downtime and increasing working flexibility. High levels of near surface resolution, penetrating power (450V pulser - square and spike) and excellent signal to noise ratio are key functions in the Masterscan range.

Typical applications are Weld Fabrication, Corrosion Detection, Composite Inspection, Bond Testing, Forgings & Castings, Power Generation (including EMATS) and general UT inspection.

Features

Reliable, Rugged & Robust

An instrument's ability to perform in harsh environments with proven reliability is an important aspect of flaw detector ownership and this is enhanced by the Masterscan's outstanding battery performance which is up to 13.5 hours from full charge. The Masterscan's enclosure is constructed using automotive grade impact resistant materials, offering excellent water resistance. Explosive Testing MIL810-G standards have been passed, together with environmental testing which has confirmed the instrument fully functioning at temperatures above 55°C. The Masterscan D-70 has a colour transflective VGA display and maximum readability is achieved through adjustable brightness and the choice of 9 colour palettes, including black-on-white LCD emulation mode.

Advanced Defect Sizing Tools as Standard

Weld and pipe inspection are major applications for the Masterscan series and they are equipped with the latest software tools for defect sizing. The use of integrated sizing software reduces analysis time and speeds inspection. Multiple standard sizing techniques are essential for service companies working to different customer standards, especially as service work becomes more international and operators are required to work to different codes.

Sizing Techniques and Software Options include:

- DAC (Standard)

- Split DAC & DGS / AVG (Option)

- TCG (Option)

- Backwall Echo Attenuation (BEA) Option (requires TCG)

- AWS (Option)

- AVG / DGS Option

- API (Option)

- Interface Trigger (Option)

- Corrosion Software (Option)

- Dryscan Function (Option)

UT-Lity Data Management Software

UT-Lity software provides everything you need to manage your inspection data. The Standard version is FREE with every instrument and give you the ability to view, move and manage Calibrations, A-Scans, B-Scans and Thickness Logs both on the instrument and on your PC. With UT-Lite you can also create customised inspection report templates, cut-n-paste information to other applications and create printable pdf documents.

- Load, store, manage files both on the PC and on a connected flaw detector

- Save, analyse, colour code and export thickness logging data to spreadsheets/asset management software

- Update the Flaw Detector and Firmware as and when updates become available on our website

Specification

| Masterscan 700m | |

| Measurement Modes | 7 modes |

| Rectification | RF, Full wave, +ve half-wave and -ve half-wave |

| Waveform Smoothing | None, Fill and Smooth |

| Aut°Cal | Provides automatic calculation of velocity and probe zero from two reference echoes |

| Reference Waveform | Displays a previously stored A-Log in a colour different from the active display: enabling a quick visual check of the differences |

| Active Peak Memory | Retains all A-Scans on screen for echo-dynamic pattern analysis, with the active A-Scan displayed in a separate colour |

| Active Edge™ | Unique Active Edge Mode for near-surface resolution |

| AGC | Automatic Gain Control automatically sets the signal in Gate 1 to a level between 10% and 90% FSH, tolerance between 5% and 20% |

| Connections | |

| Encoder | D-Sub 15 pin connector |

| External Video | YES |

| Proportional output | YES |

| External Sync | YES |

| USB Connection | Internal storage shown as Memory Device |

| Transducer sockets | BNC or LEMO (factory option) |

| Measurements | |

| Gates | 2 |

| DAC | YES |

| Split DAC | Option |

| IFT | Option |

| TCG | Option |

| AVG/DGS | Option |

| AWS | Option |

| API | Option |

| BEA | Option |

| Corrosion TLog | Option |

| BChart | Option |

| Dryscan | Option |

| Transmitter | |

| PRF | Adjustable 5Hz to 5kHz. External sync also available |

| Pulser(Voltage) | 100- 450V -ve spike and square wave |

| Pulse width from 35nS to 2500nS | |

| Rise/Fall times <15nS year | |

Accessories

Masterscan 700: BNC and LEMO

| Product Code | Description |

|---|---|

| MS700BKIT | Masterscan 700M Digital Flaw Detector BNC |

| Battery, Charger, Charger mains cable | |

| User Guide | |

| Calibration Certificate | |

| Certificate of Conformance | |

| Carry Bag | |

| UT-Lity and USB cable | |

| Display Window Cover |

Accessories & Spares

| Product Code | Description |

|---|---|

| 800208 | CH700 Battery Charger |

| 242174 | SS/MS Battery Pack |

| 195154 | DFD Storm Case |

| 145324 | Masterscan Screen Cover |

| 195121 | Masterscan Replacement Bag |

| 165027 | RCA Video Output Cable |

| 165028 | USB Type A Male Cable Assy |

| 152120 | Cable DFD to PC |

| 165040 | Falcon Proportional O/P Lead |

| 145221 | Masterscan Replacement Screen Cover |

| MPS-701EU | Flaw Detector Mains Pack |

| MPS-701UK | Flaw Detector Mains Pack |

| MPS-701US | Flaw Detector mains Pack |

| 136168 | BNC to BNC 50Ohm |

| 136169 | BNC Female to Lemo Male |

| 136171 | Lemo (M) to Lemo OO (F) |

| 152018 | BNC (M) to LEMO (F) Adaptor |

UT-Lity Pro (Advanced User Software)

UT-Lity Pro is the "professional" version and works in conjunction with the Corrosion Software option, providing the end user with the ability to create and manage inspection plans, location notes, historical thickness readings and other asset management information as required.

- Set up inspection plan (gris) templates, notes and labels

- Import previous readings into an inspection plan

- Export inspection plan data to spreadsheets and plant maintenance databases

Flaw Detector Software Options

| Product Code | Description |

|---|---|

| SW-API | API software |

| SW-AWS | AWS software |

| SW-BEA | BEA software |

| SW-CORROSION | T-Log + B-Chart software |

| SW-DGS | DGS software |

| SW-DRY | Dryscan mode software |

| SW-IFT | IFT software |

| SW-SPDAC | Split DAC software |

| SW-TCG | TCG software |

| UTILITY PRO | UT-Lity Pro software |

Downloads

Battery Information

| Type | Title | Size | Date | |

|---|---|---|---|---|

| 242174 - MSDS WAM Rev1 Feb25 | Download | 0.33 MB | 02/25 | |

| 242174 - RoHS WAM Rev1 Apr25 | Download | 0.92 MB | 04/25 | |

| 242174 - UN Declaration WAM Rev1 Nov24 | Download | 0.33 MB | 11/24 |