UT Transducers

Sonatest manufacture a complete range of high performance, high technology ultrasonic (UT) and phased array (PA) transducers for flaw detection and thickness measurement applications.

Our commitment to quality and customer satisfaction ensures that our ultrasonic transducers meet the highest standards of performance and reliability. By choosing our transducers, you benefit from:

- Expert Craftsmanship: Each transducer is hand-built by skilled technicians, ensuring meticulous attention to detail

- Advanced Technology: Incorporating the latest innovations in ultrasonic testing for superior results

- Customized Solutions: We offer the ability to customize transducers to meet your specific testing requirements

- Dedicated Support: Our team provides comprehensive support and service to assist you with your NDT needs

Features and Benefits

- High-Quality Construction: Our transducers are crafted with superior materials and craftsmanship, ensuring longevity and consistent performance

- Durable Design: Built to withstand harsh testing environments, our transducers offer robust durability for long-term use

- Precision Performance: Engineered for high sensitivity and accuracy, facilitating reliable detection and measurement of flaws and material properties

- Versatility: Suitable for a wide range of applications, making them a valuable tool for various industries

UT Transducers FAQs

- What is a transducer in ultrasonic testing?

- What are the two types of transducers in the ultrasonic sensor?

- What are 3 of the most common transducer types?

- How do I choose an ultrasonic transducer?

What is a transducer in ultrasonic testing?

In ultrasonic testing (UT), a transducer is a device that converts electrical energy into ultrasonic waves and vice versa. It serves as the heart of the ultrasonic inspection system, transmitting sound waves into the test material and receiving the echoes back. These signals are then analysed to determine the characteristics or internal flaws of the material.

We offer a comprehensive selection of ultrasonic transducers, meticulously hand-built to ensure high quality and durable construction. Designed to meet the demands of various non-destructive testing (NDT) applications, our transducers deliver exceptional performance and reliability. Whether you're conducting weld inspection, flaw detection, thickness gauging, or composite material testing, our transducers are engineered to provide precise and accurate results.

What are the two types of transducers in the ultrasonic sensor?

The two main types of transducers used in ultrasonic sensors are:

- Single-element transducers: These have one piezoelectric crystal that sends and receives sound waves. They are used for straightforward, general thickness measurements and flaw detection.

- Dual-element transducers: These feature two piezoelectric crystals placed side by side; one emits the ultrasonic waves, and the other receives the echoes.

Dual-element transducers are particularly useful in applications requiring enhanced near-surface resolution and are excellent for measuring the thickness of thin materials and corrosion inspection.

What are 3 of the most common transducer types?

Four of the most common types of UT transducers include:

- Contact transducers: These are directly placed against the material surface and are commonly used in most straightforward UT applications

- Angle beam transducers: Used to send ultrasonic waves at an angle to detect flaws in welds and structures

- Immersion transducers: Used in a water bath to inspect parts, these provide better coupling and are ideal for detailed flaw detection in complex geometries

- Through transmission: the soft tipped transducers are used in pairs, aligned on either side of the part to be inspected

How do I choose an ultrasonic transducer?

Choosing an ultrasonic transducer depends on several factors:

- Material Type: Consider the material properties, such as acoustic impedance and surface conditions

- Purpose of Inspection: Determine whether you're detecting flaws or measuring thickness, as this influences the choice

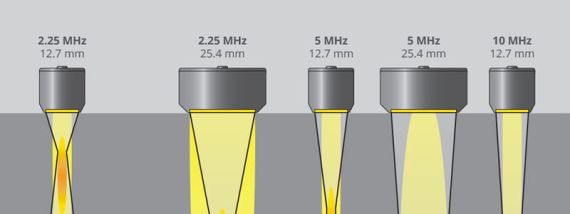

- Frequency and Size: Higher frequencies offer better resolution for thin materials, while lower frequencies penetrate deeper for thicker or highly attenuating materials

- Testing Environment: If working in harsh conditions, ensure the transducer is robust enough to handle the environment

- Technology Requirements: Consider whether a single-element or dual-element transducer better suits your needs, especially if detailed near-surface data are critical

By carefully considering these factors, you can select a transducer that best fits your ultrasonic testing needs.

Typical applications for Ultrasonic Transducers

- Weld Inspection: Detect flaws such as cracks, porosity, and lack of fusion in welds with high precision

- Flaw Detection: Identify internal defects like cracks and inclusions in materials without causing any damage

- Thickness Gauging: Accurately measure the thickness of materials to assess corrosion, erosion, or wear

- Composite Material Testing: Evaluate the integrity of composite structures in industries like aerospace, automotive, and manufacturing