- Application Notes

TFMi™ Inspection for monitoring "Blind" Holes

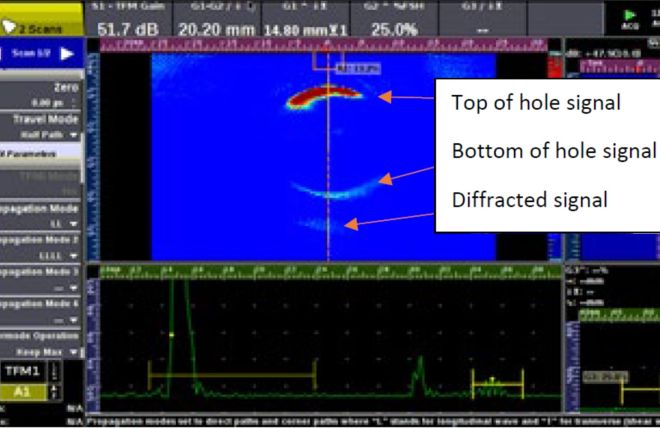

Blind hole inspection is an excellent fit for TFMi™. It really enables a full comprehensive profile view of the internal geometry of a part.

It is sometimes necessary to drill holes with very large depth-to-diameter ratios. A common approach is gun drilling, whereby a cutter is used at the end of a long rotating tool. Ensuring the alignment and consistent diameter of long holes represents an inspection challenge. The TFMi™ feature of the Veo3 provides a useful option when the hole is parallel to nearby surfaces.

Using the TFMi™ NDT technique in the Veo3, with the Intermode set to “Keep Max.” shows the reflected signal from the top surface (LL mode) and the bottom surface (LLLL mode) correctly positioned on screen. A simple gate can be used to measure the gap between them.

Filter Resources

Filter by Industry

- Aerospace Aeronautical

- Aerospace Astronautical

- Chemical & Petrochemical

- Oil & Gas

- Nuclear Energy

- Wind Power Renewables

- Transport Network Infrastructure

- Rail

- Military

- Maritime Shipping

- Automotive

- Pharmaceutical

- Mining

- Construction & Infrastructure

- Technology & Research

- NDT Service Providers

- NDT Education

Related Products